In today's fast-paced apparel industry, improving efficiency without compromising on quality is the key to staying ahead. Whether you're a small garment factory or a large-scale textile manufacturer, the way you cut your fabrics plays a major role in your overall productivity and cost-effectiveness. That's where our state-of-the-art fabric cutting machine steps in to transform your clothing production process from start to finish.

The Evolution of Fabric Cutting

Traditionally, fabric cutting involved manual labor or semi-automatic solutions that were prone to errors, inconsistencies, and significant material waste. But as technology has evolved, so has the need for smarter solutions. Our advanced automatic fabric cutting machine is designed to tackle these challenges head-on—offering unmatched precision, speed, and efficiency.

With the integration of intelligent systems, digital control, and user-friendly software, our fabric cutting machines help reduce dependence on skilled labor, lower production time, and maintain exceptional cut quality across a wide variety of materials including cotton, polyester, denim, silk, and even layered fabrics.

1

Why Fabric Cutting Efficiency Matters

Efficient fabric cutting isn't just about speed—it's about maximizing fabric utilization, minimizing waste, ensuring precision, and maintaining consistent quality. These factors collectively determine your production output, cost per unit, and customer satisfaction.

Imagine a workflow where every piece is cut perfectly, with minimal rework or rejects. That’s exactly what our fabric cutter offers. It ensures every garment component is cut to the exact size and shape, reducing fabric loss and sewing time downstream. When scaled across an entire production floor, the impact is transformative.

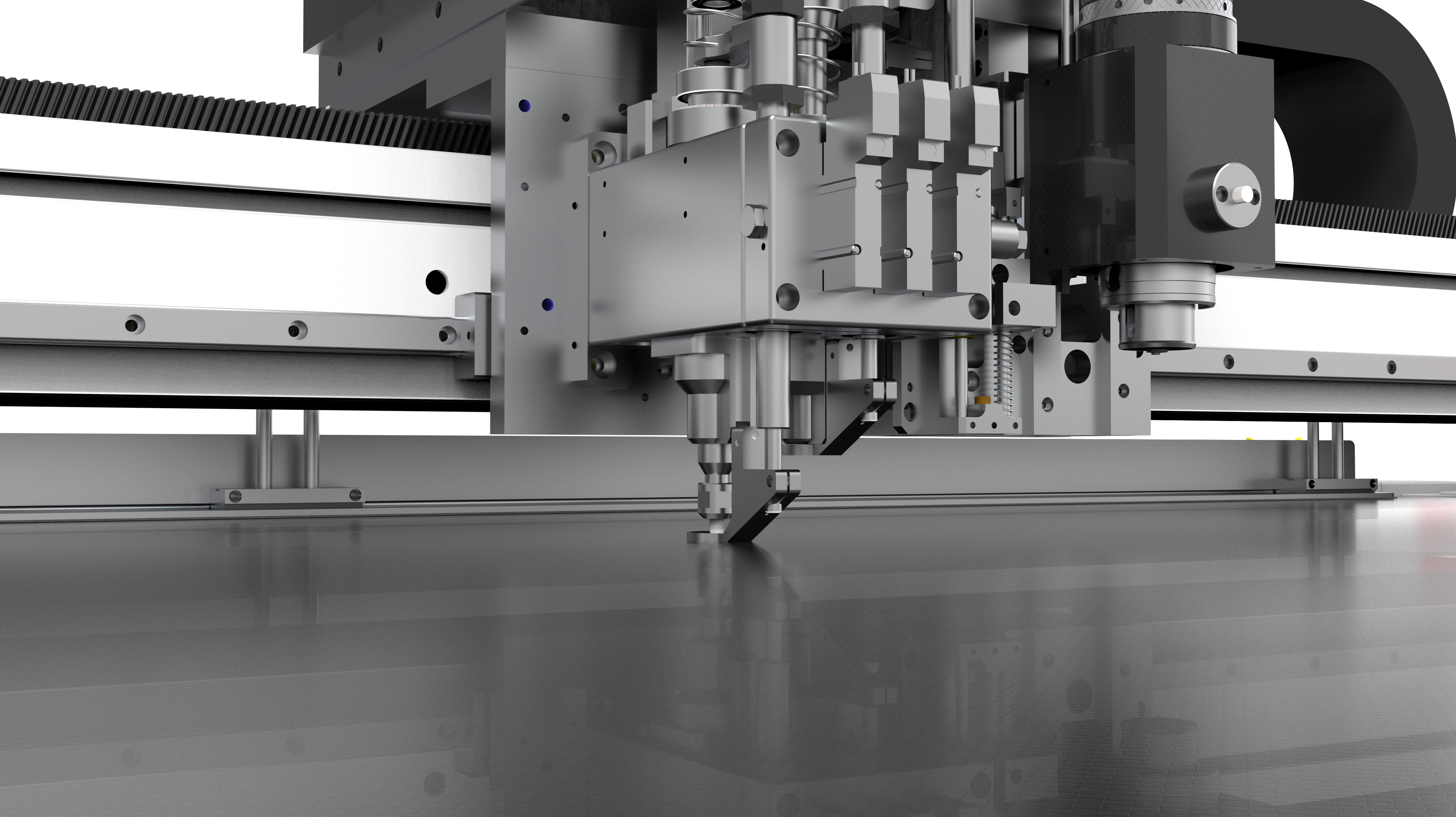

Explore the Power of Automation

Our automatic fabric cutting machine is engineered to automate complex cutting tasks with minimal operator input. With features such as auto-nesting, real-time error detection, adjustable cutting speeds, and precision blade systems, our machines allow for continuous production without interruption.By automating your cutting operations, you unlock several benefits:

Reduced labor costs

Lower error rates

Faster turnaround times

Higher output with consistent quality

Efficient handling of bulk orders

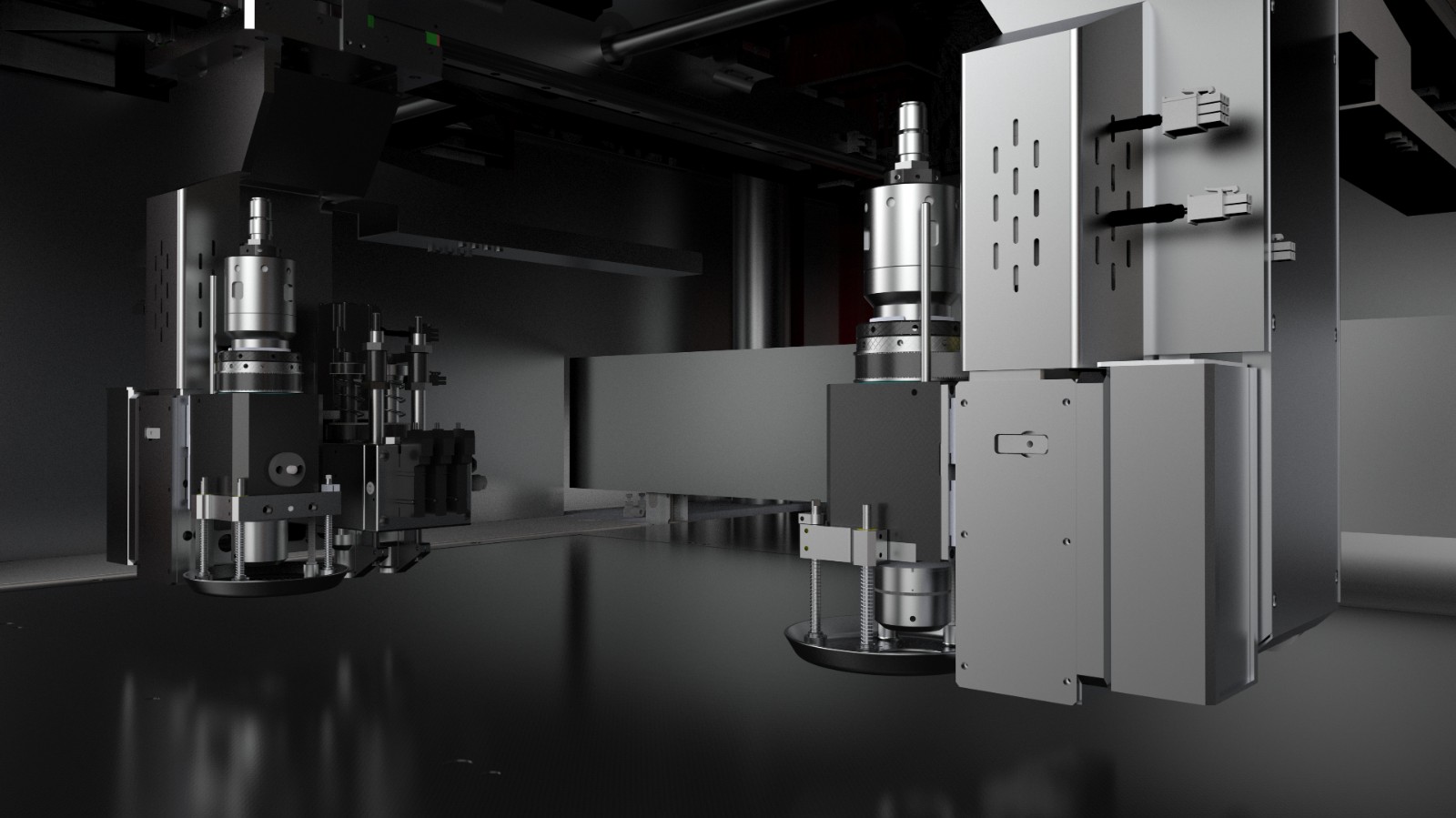

Our solutions also come with intuitive software that makes it easy to import digital patterns, optimize layout, and execute complex multi-layer cutting operations. This makes our equipment ideal for use in fast fashion, uniform manufacturing, sportswear, quilting, and home textiles.

From lightweight silk dresses to heavy-duty upholstery materials, our machines are capable of handling diverse types of fabrics. For those involved in home textiles, especially bedding and quilting, our quilt cutting machine is an invaluable asset. With its ability to accurately cut layers of quilted fabrics without distortion, it simplifies production and enhances fabric utilization.

Whether you're cutting thick quilt layers or delicate fabrics for high-end fashion, the precision and speed of our machines ensure optimal results every time.

2

Comparing Fabric Cutting Options

We offer a range of machines to suit various production needs and budgets—from compact cutters for small workshops to high-throughput industrial models. If you’re exploring options, you might be wondering about CNC fabric cutting machine price. The cost varies based on the machine's configuration, cutting area, automation level, and additional features such as multi-layer cutting, laser pointers, or vacuum tables.

However, we believe in offering competitive prices without compromising on performance. Each machine is a long-term investment that brings exponential ROI by cutting costs, reducing waste, and boosting throughput.

Whether you’re evaluating a manual cloth cutting machine or a fully digital CNC fabric cutter, consider not just the initial price, but also the long-term savings in labor, fabric, and time. Our team can help you determine the best machine based on your product line, fabric types, and production goals.

Innovation Meets Precision: Our Technology Edge

What sets our machines apart is the perfect synergy between mechanical precision and smart software. Some of the key technical highlights include:

High-speed servo motors for smooth and accurate motion control

Self-sharpening blades for consistent cutting edge

Vacuum suction tables to stabilize fabrics during cutting

Modular design for easy maintenance and upgrade

Software compatibility with multiple CAD formats and nesting systems

our machines are built with durability in mind, ensuring long-term use with minimal maintenance. This reliability makes our cloth cutting machine and other models the preferred choice for manufacturers across the globe.Understanding the true value of a CNC fabric cutting machine price involves looking beyond the number. Think about the cost of rework, fabric wastage, manual errors, and missed deadlines. With our intelligent cutting systems, these issues become a thing of the past.

Even for businesses working on tight margins, upgrading to a fabric cutter can open new avenues of growth. Faster turnaround times mean more orders fulfilled. Better precision means fewer returns. Higher efficiency means a stronger bottom line.

We also offer flexible payment options, after-sales training, technical support, and machine customization to ensure you get the most from your investment.