In today's fast-paced manufacturing world, efficiency is key to staying competitive. Packaging, an essential part of logistics and product safety, has seen significant advancements in recent years. One such innovation is the CNC cardboard cutter, which is transforming the way businesses handle packaging processes. But how exactly does this technology improve efficiency, and is it worth the investment?

What is a CNC Cardboard Cutter?

A CNC cardboard cutter is a computer-controlled machine designed to cut and shape cardboard materials with precision. Unlike traditional manual cutting methods, this machine ensures accurate, repeatable cuts, minimizing waste and maximizing productivity. With its automation capabilities, it reduces human error and speeds up production, making it a valuable asset for companies handling large volumes of packaging.

How It Compares to Traditional Cutting Methods

Traditional cutting methods rely on manual labor or semi-automated machines that often lack precision and consistency. A cardboard box cutting machine, on the other hand, can be programmed to cut different sizes and shapes efficiently. This results in:

Reduced material wastage

Faster production times

Improved accuracy and consistency

Lower labor costs

For businesses that produce a high number of custom packaging solutions, switching to a carton cutter machine can significantly boost efficiency.

Advantages of an Automatic Box Cutter Machine

The introduction of an automatic box cutter machine takes efficiency a step further by eliminating the need for constant human supervision. These machines are equipped with advanced sensors and software, allowing them to automatically adjust cutting parameters based on the material and design specifications. Key benefits include:

Increased speed and workflow optimization

Improved worker safety by reducing manual handling

Versatility in cutting different types of cardboard and corrugated materials

Integration with digital design files for seamless production

Cost Considerations: Understanding Box Cutting Machine Price

While the advantages of CNC cutting machines are clear, one important factor businesses must consider is the box cutting machine price. The cost of these machines varies depending on features such as cutting speed, automation level, and software capabilities. Entry-level machines may be more affordable but could lack the advanced functionalities needed for high-volume production. Companies should weigh the long-term savings on labor and material waste against the initial investment cost.

Is It Worth the Investment?

For packaging businesses and manufacturers, adopting a CNC cardboard cutter can lead to significant cost savings and efficiency improvements. While the upfront cost of a cardboard box cutting machine or automatic box cutter machine may seem high, the reduction in waste, labor costs, and improved production speed can result in a strong return on investment over time.

The packaging industry is evolving, and businesses must adapt to stay competitive. Investing in a carton cutter machine or an automatic box cutter machine can be a game-changer for companies looking to improve efficiency and reduce operational costs. However, understanding the box cutting machine price and choosing the right model for specific business needs is crucial. With the right machine, companies can enhance productivity and precision, ultimately leading to better customer satisfaction and profitability.

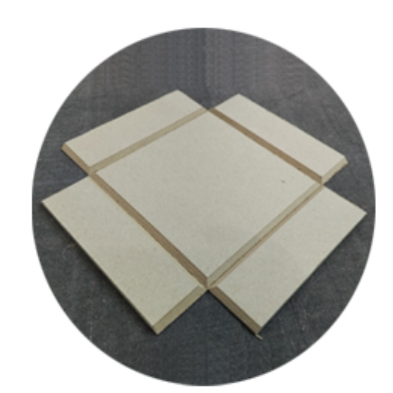

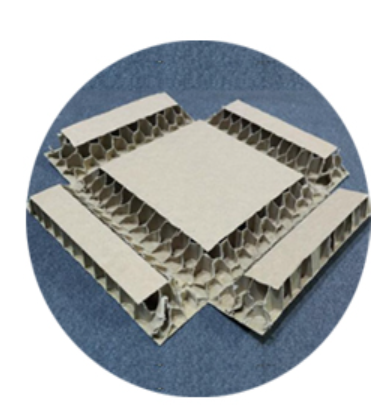

Product Sample

Product Sample

Product Sample

Product Ssmple