In today’s competitive leather manufacturing landscape, efficiency, accuracy, and flexibility are no longer optional—they’re essential. Whether you specialize in fashion accessories, furniture, footwear, or industrial-grade leather goods, every cut matters. And for many industry leaders, the solution comes down to one core question: Can one machine truly transform an entire leather production line? The answer is yes—and it begins with the right technology: a high-performance leather cutting machine designed for modern manufacturing.

The Evolution of Leather Cutting

Traditional leather cutting methods—manual blades, stamping dies, or outdated semi-automatic machines—are fast becoming obsolete. These methods not only demand excessive labor but also lack precision, waste material, and limit scalability. In contrast, today’s advanced leather cutter machines integrate smart automation, digital design, and powerful cutting capabilities, offering unprecedented control and efficiency.

To transform an entire leather production line, the machine must do more than just cut—it must optimize workflow, reduce waste, maintain consistent quality, and increase output. That’s exactly what the latest CNC leather cutting machines are built to do. These machines are equipped with intelligent motion systems, user-friendly interfaces, and precision blades that can handle complex patterns with ease.

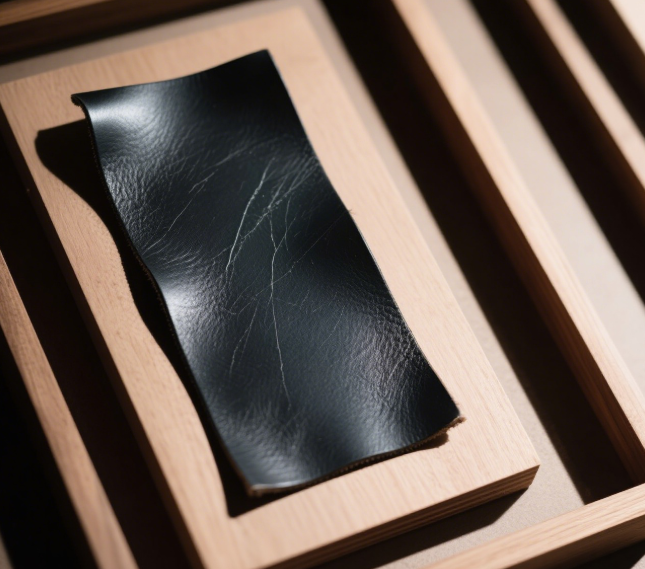

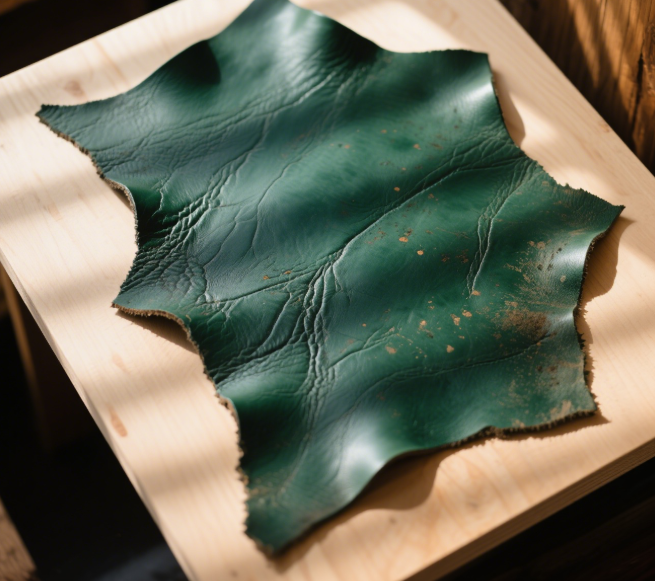

cutting sample

cutting sample

cutting sample

Key Benefits of a Modern CNC Leather Cutter:

Precision & Repeatability: Every piece is cut exactly as designed, reducing rework and material loss.

Speed & Efficiency: Cut hundreds of patterns per hour with minimal supervision.

Versatility: Suitable for natural leather, synthetic leather, PU, and composite materials.

Automation & Integration: Integrate with CAD software, barcode scanners, and ERP systems.

Scalability: Whether you’re a small workshop or a large-scale manufacturer, a CNC system grows with your business.

1

Why Choose a CNC Leather Cutting Machine?

Unlike manual or mechanical solutions, a CNC leather cutting machine brings intelligent automation to your leather production. By converting digital designs directly into cutting paths, these machines eliminate the need for templates, reduce setup time, and streamline prototyping and mass production.

The built-in software allows operators to quickly adjust cutting parameters, nest designs to minimize waste, and even monitor production data in real-time. This is why a CNC leather cutter is not just a machine—it’s a comprehensive solution that empowers your entire team, from designers to production managers.

What is the best cutting machine for leather? While the answer may vary depending on your production needs, top manufacturers are now turning to all-in-one CNC cutting solutions that combine power, precision, and adaptability.

Our latest model sets a new benchmark in leather manufacturing. Featuring high-speed servo motors, vacuum-based material fixation, and a modular drag knife system, this leather cutting machine is built for maximum efficiency. Whether you’re producing handbags, belts, upholstery, or industrial seals, this machine handles the job with unmatched speed and consistency.

Many of our clients have shared how switching to a CNC system drastically improved their production lines. One shoe manufacturer reported a 40% increase in output and a 25% reduction in material waste within three months of installing their CNC leather cutting machine. A luxury bag brand mentioned their sample-making time dropped from three days to less than one.These aren’t just improvements—they’re transformations. And they all began by asking the right question and investing in the right technology.

Can one machine transform your entire leather production line? With the right features, smart integration, and powerful automation—the answer is a resounding yes. The modern leather cutter machine doesn’t just replace manual labor; it redefines what your business is capable of.

From boosting productivity and cutting costs to achieving flawless quality, the benefits of investing in a CNC leather cutter are clear. And when you choose the best cutting machine for leather, you're not just upgrading a tool—you’re upgrading your entire operation.

If your business is ready to evolve, this is the moment to act. Let one machine unlock a new era of precision, speed, and scalability. Your future in leather manufacturing starts here.