In the fast-evolving packaging industry, efficiency, cost reduction, and sustainability are more important than ever. One cutting-edge innovation that has caught the attention of many businesses is the automatic box cutter. But can this technology really revolutionize the way we approach cardboard cutting, especially when compared to older machinery like the corrugated box cutting machine, carton cutting machine, and industrial cardboard cutting machine? This article will explore the potential of the automatic box cutter and discuss how it can surpass traditional cutting technologies like the corrugated box cutting machine and carton cutting machine.

The Challenges with Traditional Cardboard Cutting

Before diving into the advantages of the automatic box cutter, it's important to first look at the challenges associated with traditional methods. Traditional cardboard cutting machines, including corrugated box cutting machines and carton cutting machines, have been reliable for many years but come with certain limitations.

1

Labor-Intensive and Time-Consuming

Traditional machines, such as the corrugated box cutting machine and carton cutting machine, often require manual labor to operate effectively. Workers must adjust settings, monitor the cuts, and ensure that each piece is correctly sized. This can slow down production, particularly in high-volume environments.

2

Inconsistent Cutting

One of the most significant drawbacks of older cardboard cutting machines, including corrugated box cutting machines, is the inconsistency of cuts. This results in packaging errors, such as boxes that are too large or too small, which can lead to product damage and higher return rates. The lack of precision in traditional cutting processes can also contribute to more material waste.

3

Excessive Waste

Corrugated box cutting machines and other traditional cardboard cutting machines often create excess waste. Inefficient cutting patterns lead to more offcuts and excess materials that cannot be reused, ultimately driving up material costs. In an era of increasing focus on sustainability, reducing waste is more important than ever for businesses.

4

High Operational Costs

Maintaining and operating traditional industrial cardboard cutting machines requires significant investment in labor and upkeep. The need for skilled operators and frequent maintenance adds to the overall cost of production, making older machines less cost-effective in the long run.

How the Automatic Box Cutter Addresses These Issues

The automatic box cutter brings much-needed innovation to the packaging industry, offering numerous advantages over the traditional corrugated box cutting machine, carton cutting machine, and industrial cardboard cutting machine. Here’s how the automatic box cutter solves these issues:

Our advantage

Increased Speed and Efficiency

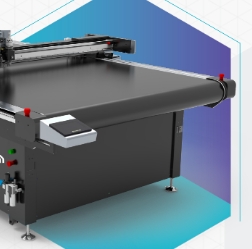

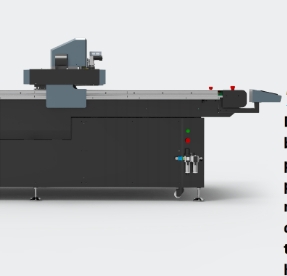

The automatic box cutter operates much faster than traditional corrugated box cutting machines and carton cutting machines. It automates the entire cutting process, reducing the need for manual intervention and allowing businesses to meet higher production demands without sacrificing quality. With improved speed and automation, the automatic box cutter streamlines the cutting process, cutting down production times significantly.

Waste Reduction

The automatic box cutter uses optimized cutting patterns to minimize offcuts and excess material, something older cardboard cutting machines, like the corrugated box cutting machine, struggle to do. By reducing waste, the automatic box cutter helps businesses cut costs and operate more sustainably. This is a key advantage over older industrial cardboard cutting machines, which often generate large amounts of waste due to inefficient cuts.

Precision and Consistency

One of the major advantages of the automatic box cutter is its ability to provide consistent, high-precision cuts. Unlike traditional corrugated box cutting machines, which may produce inconsistent results, the automatic box cutter guarantees uniformity with every cut. Whether cutting corrugated boxes or flat cardboard sheets, the machine ensures that all cuts are accurate, reducing the risk of packaging errors and wasted materials.

Cost Savings

While the initial investment in an automatic box cutter may be higher compared to traditional machines, the long-term savings are considerable. With reduced labor costs, fewer maintenance requirements, and decreased material waste, businesses can expect a quick return on investment. Unlike the carton cutting machine or corrugated box cutting machine, which require ongoing maintenance and operator oversight, the automatic box cutter reduces operational expenses significantly.

Comparing the Automatic Box Cutter to Traditional Cutting Machines

While carton cutting machines and corrugated box cutting machines have served their purpose in the packaging industry, the automatic box cutter offers several key advantages that make it a superior choice for many businesses.

1.Higher Throughput: The automatic box cutter is capable of processing a much higher volume of corrugated boxes or cardboard sheets in less time than both the carton cutting machine and the industrial cardboard cutting machine. This speed boost is especially beneficial for high-demand industries where time is of the essence.

2.Flexibility for Different Packaging Needs: Traditional corrugated box cutting machines and carton cutting machines are typically designed for a specific type of cardboard, but the automatic box cutter can handle a wider range of materials and sizes. This flexibility makes it a better choice for businesses that need to cut various types of cardboard sheets or corrugated boxes in different sizes.

3.Customizable Cuts: One of the standout features of the automatic box cutter is its ability to make custom cuts for different types of packaging. Whether businesses need small corrugated boxes for retail packaging or large boxes for industrial use, the automatic box cutter can quickly adapt to produce the necessary sizes and shapes, unlike the more rigid settings of traditional carton cutting machines and industrial cardboard cutting machines.

4.Intelligent Waste Management: Unlike older corrugated box cutting machines, the automatic box cutter often includes advanced waste management systems that automatically collect and dispose of offcuts. This reduces the time spent manually managing waste and helps keep the work area clean and efficient.

5.Lower Maintenance Requirements: Traditional cardboard cutting machines, such as the corrugated box cutting machine, require frequent maintenance and repairs. In contrast, the automatic box cutter is designed with fewer moving parts, making it more reliable and less prone to breakdowns. As a result, businesses spend less time on maintenance and more time on production.

The Future of Cardboard Cutting: Why the Automatic Box Cutter is the Future

As companies continue to push for greater speed, precision, and sustainability, the automatic box cutter is positioned to dominate the future of cardboard cutting. Its ability to reduce waste, increase efficiency, and deliver high-quality cuts makes it an ideal solution for modern businesses. Let’s explore how the automatic box cutter is shaping the future of the packaging industry:

1.Smart Automation: The automatic box cutter is built with intelligent automation systems that allow for real-time monitoring, performance optimization, and error correction. Unlike traditional corrugated box cutting machines, which often require manual adjustments, the automatic box cutter streamlines the entire cutting process.

2.Sustainability and Waste Reduction: In today’s eco-conscious world, businesses are increasingly focused on reducing their environmental footprint. The automatic box cutter helps by minimizing waste, improving material usage, and cutting down on energy consumption. These features make the automatic box cutter a valuable tool for companies that are striving for greater sustainability.

3.Customizable to Your Needs: Whether you’re cutting corrugated boxes for shipping or smaller packaging for retail, the automatic box cutter can be tailored to fit your specific needs. Its versatile design allows for quick changes between different box sizes and materials, making it an essential tool for businesses that require flexibility.