In the leather processing industry, accurate and efficient cutting equipment has always been a key factor in improving production efficiency and reducing costs. In recent years, with the development of automation and intelligent technology, CNC (Computer Numerical Control) technology has been widely used in the field of leather cutting and has become an important tool for innovating traditional processes. Among these high-precision equipment, the RUIZHOU CNC leather cutting machine stands out with its excellent performance and technical advantages and has become one of the popular equipment in the leather processing industry. So, can the RUIZHOU CNC machine cut leather? Compared with other automated leather cutting equipment, what are its unique features?

Overview of RUIZHOU CNC leather cutting machine

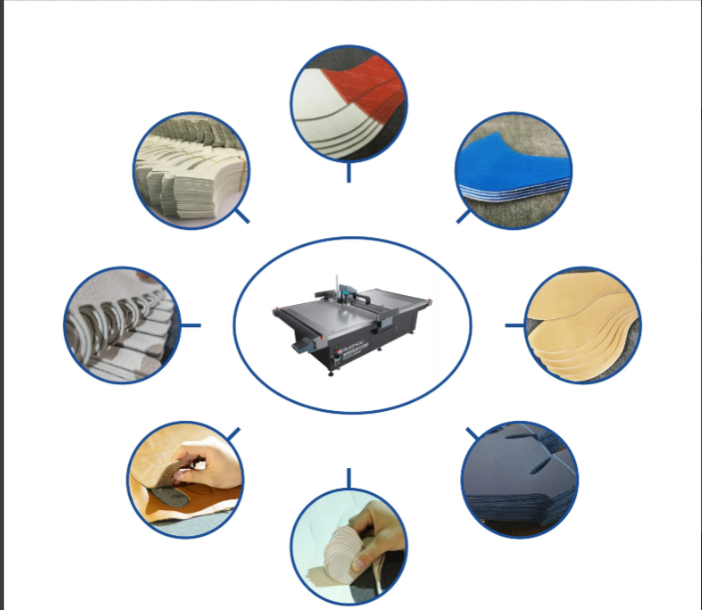

RUIZHOU is a high-tech company focusing on the research and development and production of leather cutting equipment. With innovative design concepts and exquisite manufacturing processes, its CNC leather cutting machine has been widely used in the processing of leather products. These devices can not only efficiently and accurately complete complex leather cutting tasks, but also adapt to the cutting needs of different types of leather, including soft leather, hard leather, and composite materials.

RUIZHOU's CNC leather cutting machine realizes the precise cutting of leather through a high-precision control system, a stable mechanical structure, and efficient laser or tool cutting technology. Whether it is common flat cutting, complex contour cutting, or fine engraving on the leather surface, RUIZHOU's equipment can easily handle it, ensuring that the cutting edge is flat and smooth without burrs.

The versatility of RUIZHOU CNC machines

High-precision cutting

The CNC leather cutting machine uses a computer numerical control system, which can precisely control the movement trajectory of the cutting tool to ensure that each cutting line reaches the precision required by the design. This high-precision cutting ability enables it to handle various complex cutting tasks, such as detailed leather carving, precision punching, and irregular cutting, and is widely used in the production of high-end leather products. For example, the RUIZHOU high-precision leather cutting machinecan adapt to leather materials of different thicknesses and hardnesses by adjusting cutting parameters to ensure the best cutting effect every time. Compared with traditional manual cutting, CNC machines have higher cutting precision and smaller errors, greatly improving the consistency and stability of production."

Automation and intelligence

The RUIZHOU's automated leather cutting equipment also has automated and intelligent functions. Through compatibility with advanced CAD/CAM design software, designers can directly import design drawings into the CNC machine, and the machine automatically completes the cutting operation according to the drawings. This process not only improves production efficiency but also reduces the interference of human factors and lowers operational risks. More importantly, the popularization of the automated leather cutting machine can achieve continuous work in large-scale production and operate uninterrupted for 24 hours, significantly increasing the production capacity of the production line and reducing labor costs. For factories engaged in large-scale production, the investment in an automated system can not only improve cutting efficiency but also reduce errors and increase overall output value.

Improve production efficiency

Compared with traditional manual cutting, the production efficiency of CNC leather cutting machine is significantly improved. Especially when a large number of leather products with the same or similar shapes need to be cut, RUIZHOU's automated leather cutting machine can quickly complete mass production without human intervention. The degree of automation of the equipment not only reduces the time required for manual operation but also can accurately and flawlessly replicate each product, thereby improving production efficiency and product delivery speed.

Reduce waste and save materials.

In leather processing, material waste has always been a difficult problem faced by the industry. The precise design of the CNC leather cutting machine enables each cut to utilize materials to the greatest extent and reduce the generation of waste materials. Through the intelligent layout of computer software, the utilization rate of leather materials can be maximized, further reducing production costs.

Future development trends With the continuous progress of technology, the technology of CNC leather cutting machine is also constantly evolving. In the future, CNC leather cutting equipment will develop in a more intelligent, automated, and precise direction. For example, combined with artificial intelligence (AI) technology, future CNC cutting machines may be able to automatically optimize cutting according to the characteristics of leather materials and design requirements, improving cutting efficiency and accuracy. At the same time, the operation interface of the equipment will be more friendly, and operators can adjust and monitor more conveniently, further improving the automation level of the production line. In addition, with the increase in environmental awareness, future CNC leather cutting equipment will pay more attention to energy conservation and environmental protection. For example, by adopting a low-energy consumption drive system and an efficient cutting process, energy consumption and material waste can be reduced. Combined with big data technology, the equipment will be able to monitor the production status in real time and predict equipment maintenance and failures, thereby improving the service life of the equipment and the overall production efficiency.

The RUIZHOU's CNC leather cutting machine, with its excellent cutting precision, automated operation and efficient production capacity, has become one of the important equipments in the modern leather processing industry. With the continuous progress of technology, the future CNC leather cutting equipment will be more intelligent and refined, helping enterprises achieve more efficient and environmentally friendly production goals. For leather product manufacturers, choosing a high-quality automated leather cutting equipment will undoubtedly be a key step in improving market competitiveness and product quality.

4o