In recent years, CNC leather cutting machines have become the cornerstone of efficiency and precision in the leather industry. As consumer demands for customized and intricate designs grow, traditional methods of leather cutting have struggled to keep up with the speed and complexity required. Fortunately, technological advancements such as shoe leather cutting machines, CNC knife cutting machines, PU leather cutting machines, and digital cutting machines have revolutionized the industry by significantly improving cutting accuracy, material utilization, and overall production efficiency.

The power of precision

At the heart of this transformation are CNC leather cutting machines. These advanced systems use Computer Numerical Control (CNC) technology to automate and optimize the cutting process. The biggest advantage of CNC leather cutting machines lies in their incredible precision. With a cutting accuracy of up to ±0.1mm, these machines are capable of producing intricate designs and patterns on leather materials with extreme precision. This precision is vital for manufacturers of leather goods, such as bags, jackets, belts, and upholstery, where consistency and accuracy in each cut are essential.

The CNC leather cutting machine operates using digital designs that are transferred from a computer to the cutting system. By interpreting these designs into precise cutting commands, the machine can cut leather in various shapes and sizes without human intervention. This eliminates the possibility of human error, ensures repeatability, and speeds up production, allowing for mass customization while maintaining high-quality standards.

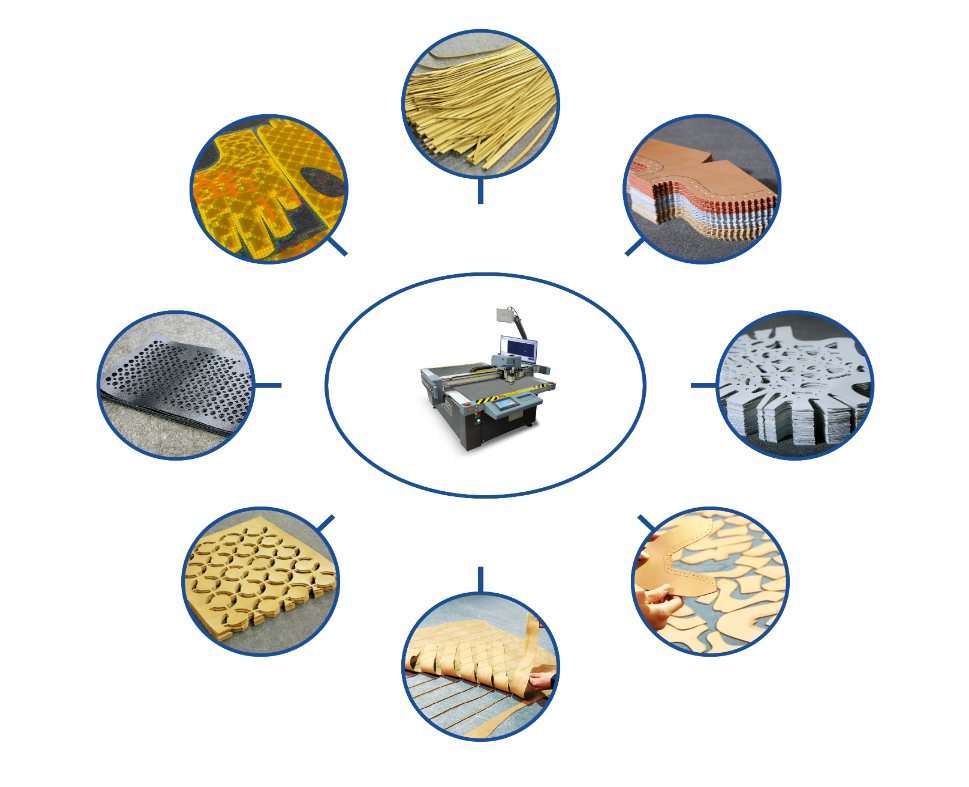

These machines are versatile, handling various leather types—such as full-grain, top-grain, and bonded leather—across multiple thicknesses. For manufacturers working with different leather materials, the CNC leather cutting machine allows easy adjustments to handle a variety of textures, providing a high level of flexibility in production.

Tailoring Precision for Footwear

A specialized subset of the CNC leather cutting machine is the shoe leather cutting machine. This machine is designed specifically for the footwear industry, where precision and efficiency are paramount. Whether for high-end fashion shoes, athletic footwear, or custom designs, shoe leather cutting machines can handle the complex cutting tasks required for shoe components such as uppers, linings, insoles, and outsoles.

One of the standout features of shoe leather cutting machines is their ability to cut leather in multiple layers simultaneously. In shoe production, it’s essential to cut several pieces of leather at once to maintain efficiency. These machines can layer and cut leather in one go, dramatically speeding up the production process.

Shoe leather cutting machines often come with software that allows manufacturers to create patterns and design layouts optimized for material usage. This ensures that the leather is used as efficiently as possible, reducing material waste, and cutting costs. By combining speed with precision, shoe leather cutting machines make it possible to produce high volumes of footwear components that meet the demanding quality standards of the footwear industry.

Versatility Across Materials

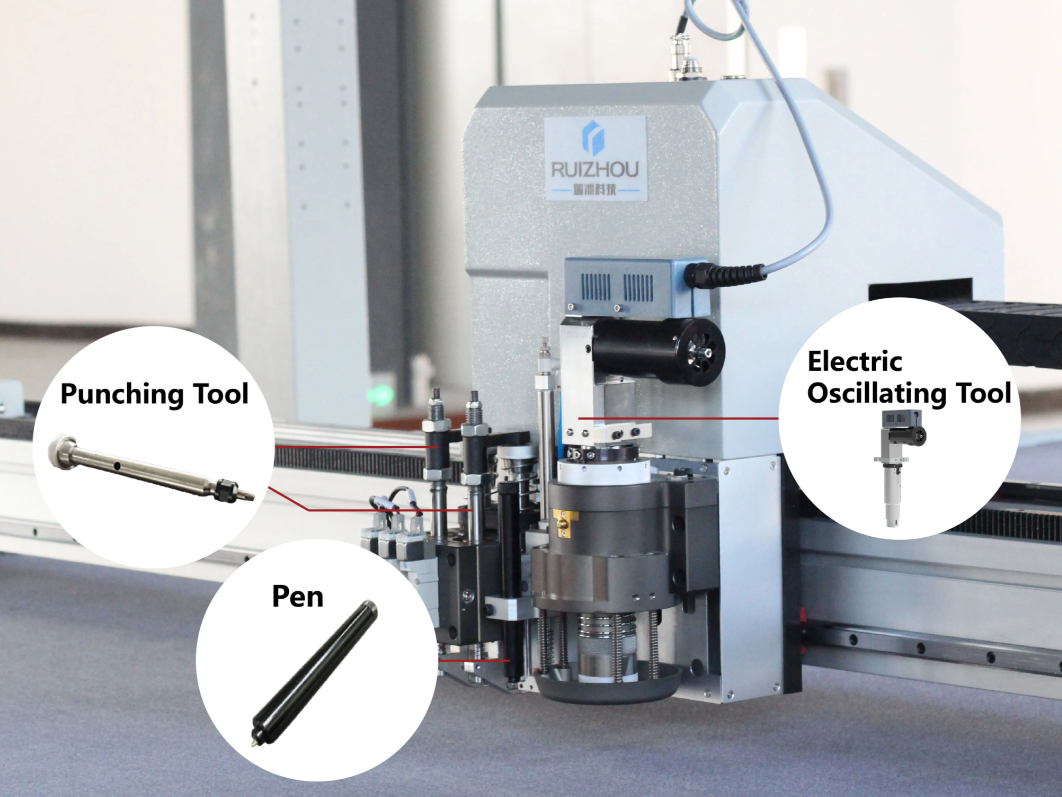

Another key player in the evolution of leather cutting is the CNC knife cutting machine. Unlike traditional cutting methods, which rely on blades or rotary cutters, CNC knife cutting machines use a motorized blade controlled by a computer to cut through leather and other materials. These machines are incredibly versatile, capable of cutting through various materials beyond leather, including rubber, fabric, foam, and synthetic materials.

The precision offered by CNC knife cutting machines makes them ideal for industries where intricate designs are required, such as automotive interiors, fashion, and upholstery. For example, in automotive manufacturing, CNC knife cutting machines can be used to cut leather for car seats, door panels, and other interior components, ensuring that each piece fits perfectly and aligns with the overall design.

Paving the Way for the Future

The future of leather cutting lies in digital cutting machines, which combine advanced software and cutting technology to provide even greater flexibility and precision. Unlike traditional cutting machines, digital cutting machines operate without the need for physical patterns or templates. Instead, they use digital files, such as CAD drawings, to guide the cutting process.

With digital cutting machines, manufacturers can also integrate cutting with other processes, such as engraving, embossing, or even stitching, all within a single machine. This level of integration reduces the need for multiple machines and streamlines the production process, saving both time and costs.

As the leather industry continues to evolve, the integration of CNC leather cutting machines, shoe leather cutting machines, CNC knife cutting machines, PU leather cutting machines, and digital cutting machines is leading the way in terms of efficiency, precision, and sustainability. These machines are not only reducing material waste and production time but also opening up new possibilities for customization and design.By embracing automation and digital cutting solutions, the leather industry is well-equipped to meet the demands of the modern consumer, offering high-quality, customized products faster and more efficiently than ever before. The future of leather cutting is digital, and these machines are driving the revolution forward.