As the global bag manufacturing industry accelerates toward full digitalization and flexible production, the three core indicators—speed, precision, and cost—have become the decisive factors shaping competitiveness. With order cycles shortening and product variations increasing, traditional manual cutting methods can no longer meet modern manufacturing requirements for efficiency, quality, and traceability. In this industry transformation, RUIZHOU launches its new-generation intelligent automatic bag cutting machine, elevating performance to a new benchmark and empowering factories to achieve high-speed, high-efficiency, and highly consistent production output.Backed by years of expertise in intelligent cutting technology, RUIZHOU—one of China’s leading cnc cutting machine factory—has comprehensively upgraded its control system, tool structure, vacuum system, and motion algorithms. The new bag cutting machine achieves a remarkable speed boost, driven by high-performance servo motors and intelligent path-planning algorithms. Cutting speed, cornering speed, and acceleration are significantly enhanced, enabling factories to “produce more within the same time” while reducing rework and material waste caused by manual inconsistencies.In flexible bag production, materials such as PU, PVC, synthetic leather, and textiles demand exceptionally clean edges and stable cutting trajectories. Drawing from extensive long-term service provided to major bag-brand supply chains, RUIZHOU developed a specialized PU cutting solution that allows the pu bag cutting machine to deliver smooth edges without burning, fraying, stretching, or roughness, even during high-frequency continuous cutting operations.

1

Ruizhou automatic bag cutting machine comprehensively improves production speed

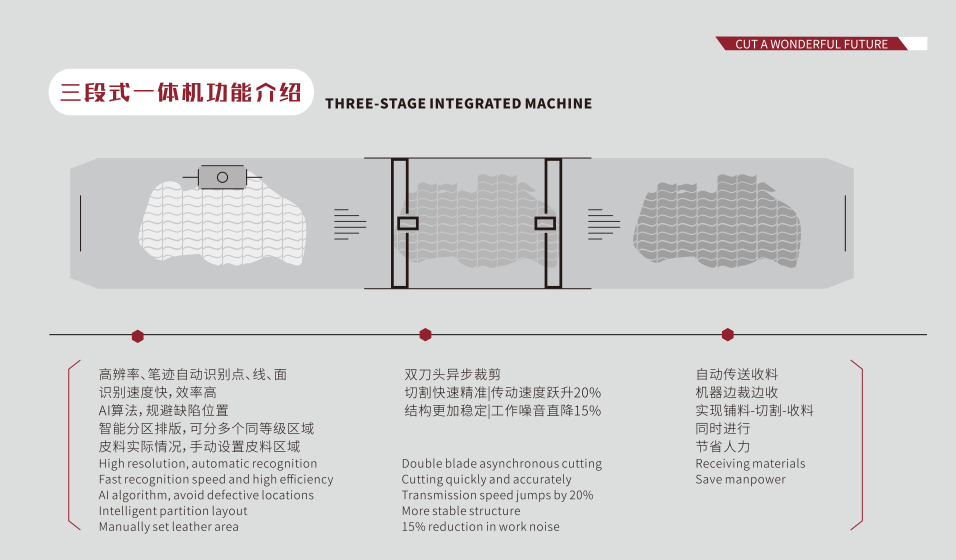

Furthermore, the intelligent cnc cutting machine integrates a high-definition camera and visual-positioning system capable of accurately identifying print positions, texture directions, and stripe alignments. Combined with AI-powered nesting software, material utilization can be increased by 6%–18%, providing significant cost savings for manufacturers facing rising material prices. For factories producing PU soft bags, nylon bags, laptop sleeves, sports backpacks, and other flexible products, one machine can cover most cutting needs, enhancing order flexibility.In terms of efficiency, the new automatic bag cutting machine delivers industry-leading speed performance. Compared to manual cutting, efficiency increases by 3–5 times; compared to previous-generation systems, optimized path planning delivers an additional 25% production boost. For factories handling fast e-commerce replenishment, small-batch and multi-batch orders, or highly customized products, the increased cutting speed directly translates into stronger delivery capacity and higher market responsiveness.

Intelligent functionality is another highlight of the upgrade. The system features automatic knife-depth adjustment, adjustable vacuum strength, edge detection, and material batch tracking. These functions not only enhance cutting precision but also help build a traceable digital production environment. RUIZHOU’s intelligent nesting system solves common challenges such as complex patterns, frequent style changes, and slow manual nesting, enabling quick file import, overlap detection, and automated layout optimization—saving substantial preparation time.

As a mature cnc cutting machine factory, RUIZHOU has delivered intelligent cutting solutions to customers in more than 30 countries and regions. It has accumulated extensive success cases across premium backpacks, business luggage, electronic device bags, and sports-equipment bags. Manufacturers commonly report that the new cutting system not only increases production output but also significantly reduces dependence on experienced manual cutters, making the production process more stable and predictable.

Ruizhou's automatic bag cutting machine goes online, helping bag factories achieve a leap in production capacity.

RUIZHOU also understands that manufacturers focus on ROI when investing in equipment. Therefore, each bag cutting machine is engineered with long-term cost optimization in mind. A modular design allows independent maintenance of the tool head, vacuum modules, and worktable, reducing downtime. Longer consumable life cycles stabilize operational costs, while online remote diagnostics monitor machine status in real time, reducing failure rates and shortening service response times.As global manufacturing accelerates toward digital and automated production, building intelligent factories has become essential—whether for traditional bag manufacturers or rapidly expanding supply chains. RUIZHOU’s intelligent cutting solutions offer not just a single cnc cutting machine, but a complete digital platform spanning design, nesting, cutting, and production management, enabling factories to process more orders faster while supporting both mass production and flexible manufacturing.To learn how RUIZHOU’s intelligent automatic bag cutting machine can boost production, increase material utilization, and reduce labor dependency, please visit the official website:www.ruizhoucnc.com

RUIZHOU will continue driving industry advancement through technological innovation, providing global bag manufacturers with more efficient, intelligent, and competitive digital cutting solutions.