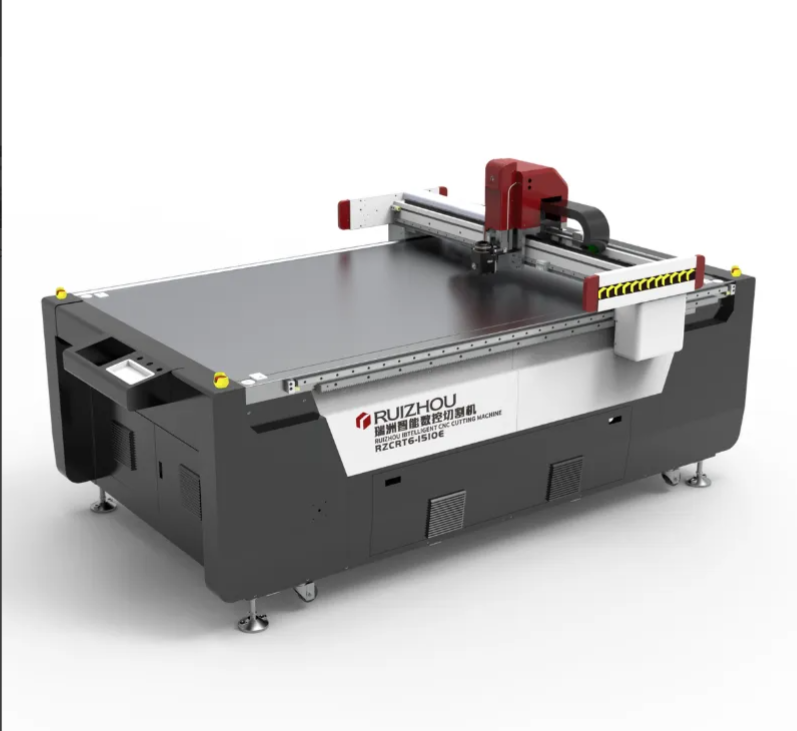

In today’s fast-evolving packaging and fabrication industry, precision is no longer just a luxury—it’s a necessity. Whether you're crafting custom packaging solutions, creating detailed prototypes, or manufacturing displays, the demand for accuracy and efficiency has never been higher. At the heart of this transformation lies the CNC cardboard cutter, a machine that’s redefining how cardboard and similar materials are handled in both small and large-scale production environments.

The Rise of the CNC Cardboard Cutter

CNC (Computer Numerical Control) technology has long been a staple in industries like metalworking and woodworking. Now, its precision capabilities are being applied to more delicate materials like corrugated cardboard, KT board, and other composite panels. A CNC cardboard cutter operates with incredible accuracy, driven by digital designs that eliminate manual error and reduce waste.

Modern CNC cutters for cardboard boast tolerances as tight as ±0.1mm, a level of precision that was previously difficult to achieve with traditional tools. For industries that depend on clean lines and perfect folds—such as luxury packaging, retail POP displays, and custom shipping boxes—this level of detail is transformative.

Beyond the Basics: Cardboard Box Cutting Machines

A cardboard box cutting machine might sound like a simple tool, but the latest iterations are anything but basic. These advanced machines are now equipped with smart sensors, AI-driven layout optimization, and software that integrates seamlessly with 3D modeling platforms. As a result, users can go from digital prototype to physical box in a matter of minutes.

What sets these machines apart is their ability to cut and crease in a single operation. This dual-functionality dramatically reduces the time it takes to produce high-quality boxes and custom packaging solutions. For manufacturers, this means faster turnaround times, better material utilization, and improved consistency across production runs.

The Role of the Automatic Box Cutter

The automatic box cutter is another innovation reshaping the industry. Unlike manual or semi-automatic machines, today’s automatic cutters are fully programmable and often operate unattended. With conveyor-fed systems and barcode scanning for job recognition, they can handle complex workflows with minimal human intervention.

Automatic box cutters are particularly popular in e-commerce fulfillment centers, where demand for custom-sized boxes is high. Instead of storing hundreds of box sizes, companies can create perfectly fitted boxes on demand, improving efficiency and reducing shipping costs. This shift toward automation is not only improving productivity but also enabling businesses to scale without a proportional increase in labor costs.

Precision in KT Board Cutting

KT board—also known as foam board—is widely used in signage, exhibition displays, and architectural modeling. Cutting this material requires a careful balance between sharpness and pressure, as excessive force can cause fraying or crushed edges. That’s where CNC and digital cutting machine technology comes in.

Modern KT board cutting processes rely on advanced blade systems and adjustable pressure settings, allowing operators to fine-tune their machines for different board densities and thicknesses. Some machines even feature oscillating blades or laser modules to handle detailed cuts or internal perforations.

By using a CNC system, KT board can be cut into complex shapes with millimeter-level precision, ensuring perfect fits in multi-panel displays or architectural models. This level of detail is essential for clients who expect professional, clean, and structurally sound finishes.

Product Sample

Product Sample

Product Sample

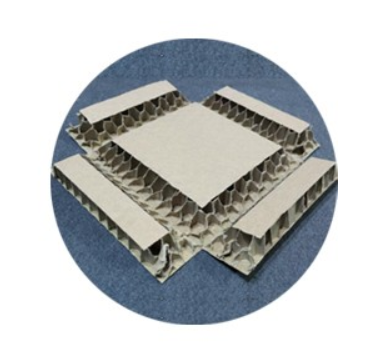

Product Sample

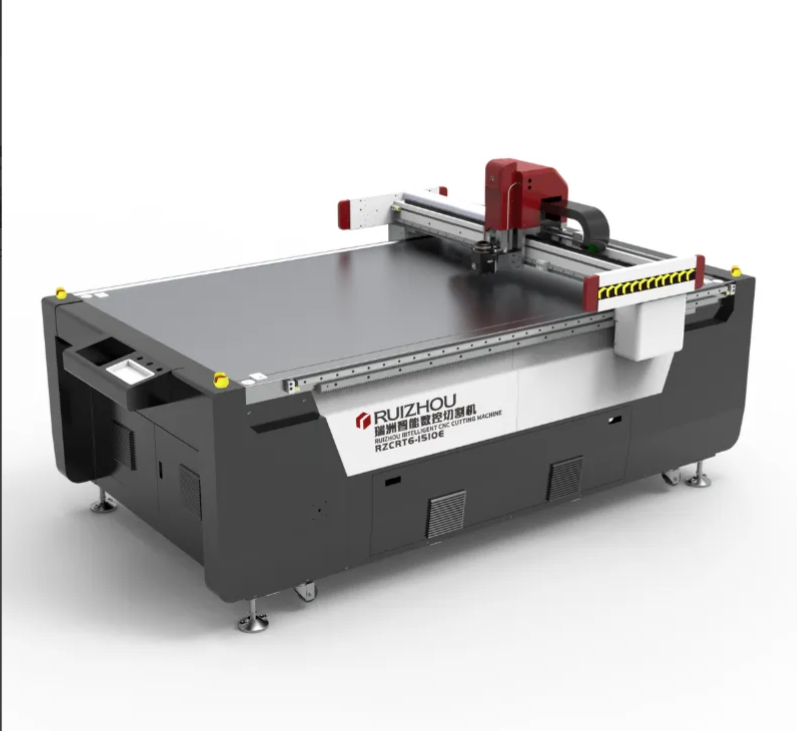

Enter the RUIZHOU Digital Cutting Machine Era

At the center of this technological evolution is the digital cutting machine. These machines are not limited to just cardboard—they handle a wide range of substrates including foam board, vinyl, corrugated plastic, leather, and more. Digital cutting technology allows for tool changes, automatic calibration, and integration with cloud-based design platforms.

The most advanced machines can read multiple file formats, auto-nest patterns to reduce material waste, and even use vision systems to align cuts with pre-printed graphics. This versatility makes digital cutters indispensable tools for modern manufacturing, packaging, and creative industries.

One of the major advantages of a digital cutting system is its adaptability. As product lines change and client demands evolve, manufacturers can quickly pivot—there’s no need for costly dies or time-consuming setup. The result? Faster time to market, more personalized offerings, and significantly reduced overhead.

how precise is today’s CNC cardboard cutter? In short—extremely precise. But more than that, it's a gateway to a smarter, more flexible, and highly efficient production workflow. From cardboard box cutting machines to automatic box cutters, and from KT board cutting to multifunction digital cutting machines, the landscape is shifting rapidly.

Businesses that invest in this new generation of cutting equipment are finding themselves ahead of the curve—reducing waste, increasing customization capabilities, and delivering higher-quality products in less time.

As digital fabrication continues to evolve, one thing is clear: precision isn’t just a performance metric anymore. It’s a competitive advantage.