The textile industry has always been one of the pillars of global manufacturing, influencing everything from fashion to home goods.As the demand for faster production, more precise cuts, and reduced labor costs increases, traditional methods of fabric cutting are becoming less efficient. This is where automated fabric cutters come in. These advanced machines are set to transform the way textiles are cut, spread, and manufactured. Let’s explore how automatic fabric cutting machines are not only improving the production process but also driving the future of the textile industry.

The Need for Innovation in Fabric Cutting

In the past, fabric cutting was a manual process that required a significant amount of human labor. Workers had to carefully spread the fabric, measure it, and use tools like scissors or knives to cut it into the desired shapes. While this process worked well for smaller operations, it is no longer feasible in today’s fast-paced, high-demand market. The industry needs solutions that provide precision, efficiency, and scalability.

This is where the advent of the automatic cloth cutting machine and its associated technologies comes into play. Automated systems are becoming a game-changer in fabric cutting, offering unparalleled speed, accuracy, and cost-effectiveness. By integrating automation into the cutting process, textile manufacturers can increase production rates, reduce material waste, and lower labor costs.

What is an Automated Fabric Cutter?

An automated fabric cutter is a device designed to perform the cutting process with minimal human intervention. These machines use advanced technologies like lasers, knives, or water jets to cut fabric with extreme precision. They are programmed to follow specific patterns and measurements, ensuring that every cut is exactly where it should be, without any deviations.

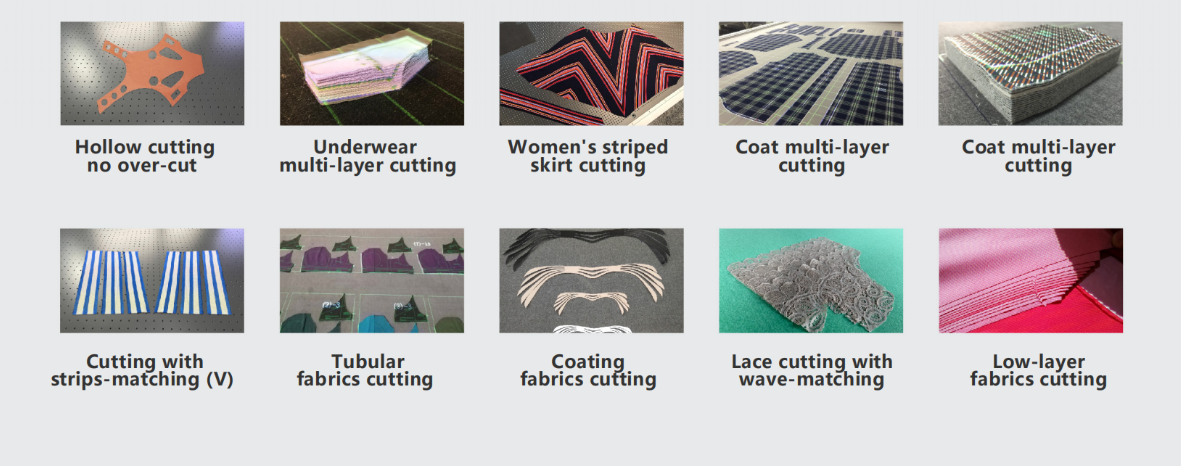

The integration of automatic fabric cutting machines in production lines has opened up possibilities for large-scale manufacturers to meet the demands of the modern textile industry. The system works by automatically spreading the fabric across a cutting table, analyzing the material, and determining the most efficient way to cut it. Whether dealing with delicate fabrics like silk or heavy-duty materials like denim, these machines are designed to handle a wide range of textile types.

Benefits of Automated Fabric Cutters

Increased Efficiency

One of the biggest advantages of automatic textile cutting machines is the dramatic increase in efficiency they offer. Traditionally, fabric cutting was a time-consuming process that required manual labor to spread, measure, and cut. With automation, these machines can process large volumes of fabric in a fraction of the time. The speed at which these machines operate significantly reduces production time and increases the overall throughput of the manufacturing process.

An automatic spreading and cutting machine can lay down multiple layers of fabric and cut them simultaneously, greatly reducing the time spent on each batch. This leads to faster turnaround times for orders, enabling textile manufacturers to meet the demands of fast fashion and other industries with much greater ease.

Precision and Accuracy

Automated fabric cutters are designed to deliver a level of precision that far surpasses human capabilities. The risk of human error, such as miscalculating measurements or making inconsistent cuts, is eliminated. This ensures that each garment or textile product is cut to exact specifications, reducing the need for rework or waste.

With the high precision of automatic fabric cutting machines, manufacturers can work with complex patterns and intricate designs that would otherwise be difficult or impossible to achieve manually. This is particularly useful for high-end fashion brands and specialized textile products, where quality and detail are paramount.

Cost Reductione

While the initial investment in an automatic cloth cutting machine may be substantial, the long-term cost savings are significant. The reduction in labor costs, fewer errors, and minimized material waste all contribute to lower production costs. These machines operate with high efficiency, ensuring that every yard of fabric is used effectively, leading to significant cost savings over time.

Sustainability

Sustainability has become a key concern in the textile industry, and automated fabric cutting systems are helping manufacturers reduce their environmental impact. Traditional fabric cutting processes often result in significant fabric waste, as manual methods may lead to inefficient use of materials. With automatic textile cutting machines, the cutting process is optimized to minimize waste, allowing manufacturers to make the most out of every yard of fabric.

By automating the fabric spreading process, automatic spreading and cutting machines help ensure that the fabric is evenly distributed, which reduces waste caused by misalignment. This can lead to more sustainable production practices, which is crucial as consumers increasingly demand eco-friendly products.

The rise of automated fabric cutters represents a significant shift in the textile industry, offering manufacturers a way to improve efficiency, accuracy, and sustainability. As automatic fabric cutting machines continue to evolve, they will further revolutionize the way textiles are produced, enabling faster turnaround times, reduced costs, and more precise production. With the growing demand for faster production cycles, higher-quality goods, and environmentally friendly practices, automatic spreading and cutting machines are poised to become an indispensable tool in the textile industry, driving innovation and shaping the future of fabric manufacturing.