The manufacturing industry is constantly evolving, and one sector seeing rapid transformation is leather production. As global demand for leather goods continues to grow, manufacturers are looking for innovative solutions to improve efficiency, precision, and productivity. One question on everyone’s mind: Is the leather cutting machine the future of manufacturing?

In the past, leather cutting was labor-intensive and time-consuming, relying heavily on manual craftsmanship. However, advancements in technology have introduced automated solutions, notably the CNC leather cutting machine, revolutionizing how manufacturers approach leather processing.

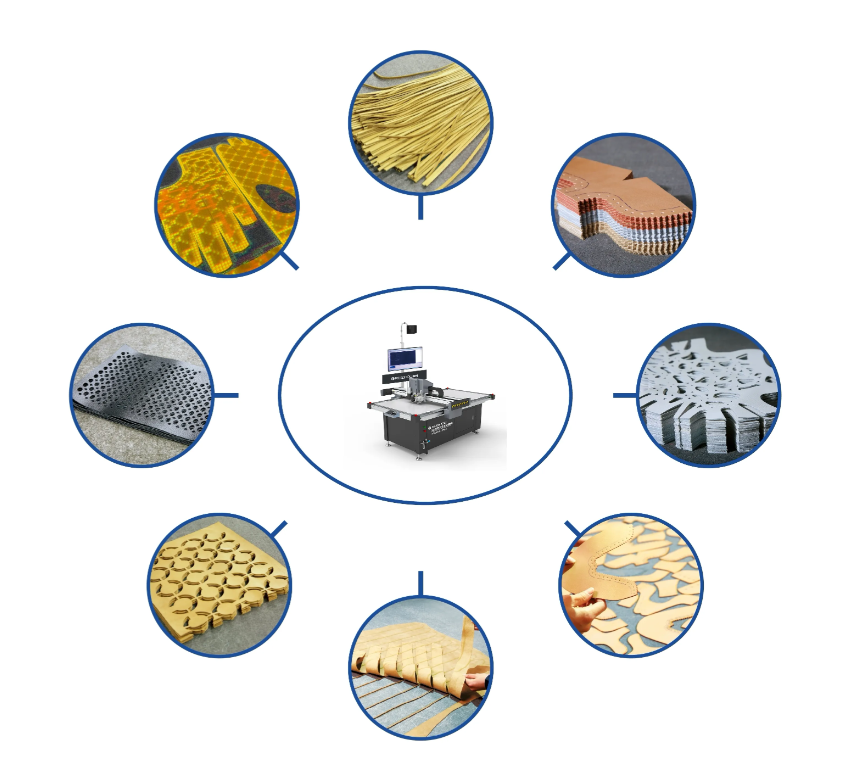

A CNC leather cutting machine offers several advantages over traditional methods. Using computer numerical control (CNC) technology, these machines can cut intricate patterns with absolute accuracy. Whether producing luxury bags, automotive interiors, or footwear, manufacturers can rely on a CNC leather cutting machine to deliver consistent results with minimal waste. Furthermore, CNC systems reduce human error, saving time and resources while enhancing overall production efficiency.

RUIZHOU

Another essential tool in modern leather manufacturing is the leather strip cutter. These machines are specifically designed to cut leather into precise strips for belts, straps, and decorative elements. A high-quality leather strip cutter allows for uniform sizing and clean edges, which are crucial for producing premium leather products. In addition to improving accuracy, these cutters drastically reduce labor and speed up the production line.

Different Types of Leather Cutting Machines

The trend toward automation is further emphasized by the growing adoption of the automatic leather cutting machine. Unlike manual cutting or semi-automatic options, an automatic leather cutting machine operates independently, processing large volumes of leather with impressive speed and accuracy. Such machines are ideal for large factories aiming to meet high-demand markets without compromising quality. From industrial-grade footwear manufacturers to automotive upholstery producers, the benefits of automatic cutting cannot be overstated.

Market demand for leather cutting machines grows

For businesses looking to stay ahead of competitors, investing in cutting-edge machinery is crucial. This has led to an increase in demand for the leather cutting machine for sale. Companies are actively searching for reliable equipment suppliers who can offer advanced machines at competitive prices. Whether purchasing a CNC leather cutting machine, a leather strip cutter, or an automatic leather cutting machine, manufacturers are evaluating key factors such as durability, precision, speed, and cost-effectiveness.

Manufacturers also consider how easy the machine is to integrate into their existing production line. Modern machines come with user-friendly interfaces, allowing operators to program designs quickly and switch between different product types with minimal downtime. Smart features, like auto-nesting software, maximize material usage and reduce waste, further contributing to profitability.

Future development trends

The sustainability aspect cannot be ignored. Efficient cutting reduces material waste and energy consumption, aligning with global efforts to reduce environmental impact. As leather processing evolves, machines that offer both speed and environmental efficiency are highly valued.

The global market for leather cutting machine for sale is expected to grow significantly in the coming years. Manufacturers from various industries — including fashion, automotive, and furniture — are making large investments in these technologies. The integration of smart manufacturing techniques, AI-driven design inputs, and IoT monitoring systems further enhance the appeal of modern leather cutting solutions.

Companies that fail to adopt new technologies risk falling behind. With rising labor costs and increasing competition, traditional manual methods are no longer sustainable for mass production. By embracing solutions like the CNC leather cutting machine and automatic leather cutting machine, manufacturers can increase output, maintain top-tier quality, and reduce operational costs.

There is also an increased focus on machine versatility. A high-end leather cutting machine can process a wide range of leather types, from thick, rigid materials to delicate, flexible ones. Multi-functional machines that can switch between cutting, perforating, and embossing are becoming particularly popular. The more functions a single machine can perform, the greater the return on investment for manufacturers.

Safety features are another consideration. Today’s leather cutting machine models are equipped with advanced safety mechanisms, including emergency stop functions, motion sensors, and protective barriers, ensuring the well-being of workers.

Choose RUIZHOU Leather cutting machine

Market leaders in the leather cutting machine for sale sector are also focusing on offering customized solutions. Manufacturers may require machines tailored to their specific production needs, including custom blade configurations, variable cutting speeds, and specialized software to accommodate unique patterns.

Training and support services are vital components of purchasing decisions. Suppliers who offer comprehensive training packages and 24/7 technical support have a competitive edge. After all, even the most advanced machine can fall short if operators are not well-trained.

Looking ahead, the future seems bright for leather manufacturers who invest in advanced technology. As more businesses recognize the benefits of machines like the CNC leather cutting machine, leather strip cutter, and automatic leather cutting machine, we can expect production lines to become more efficient, environmentally friendly, and profitable.