In an age of rapid e-commerce growth, rising consumer expectations, and a global push toward sustainable packaging, the packaging industry is undergoing a major transformation. At the center of this shift is a new generation of intelligent machinery designed to meet the increasing demand for fast, customized, and eco-friendly packaging. Among the standout technologies leading this transformation is the Precision Cardboard Box Cutting Machine for Modern Factories—a highly advanced, automation-driven solution that is changing the way boxes are made.

Meeting the Demands of the Modern Production Line

Today’s production environments require more than just basic functionality—they demand smart, connected, and efficient systems. The cardboard box cutting machine is purpose-built to address these needs. Whether it’s a high-speed production floor or a flexible custom packaging operation, this machine delivers the speed, precision, and automation manufacturers need to stay competitive.

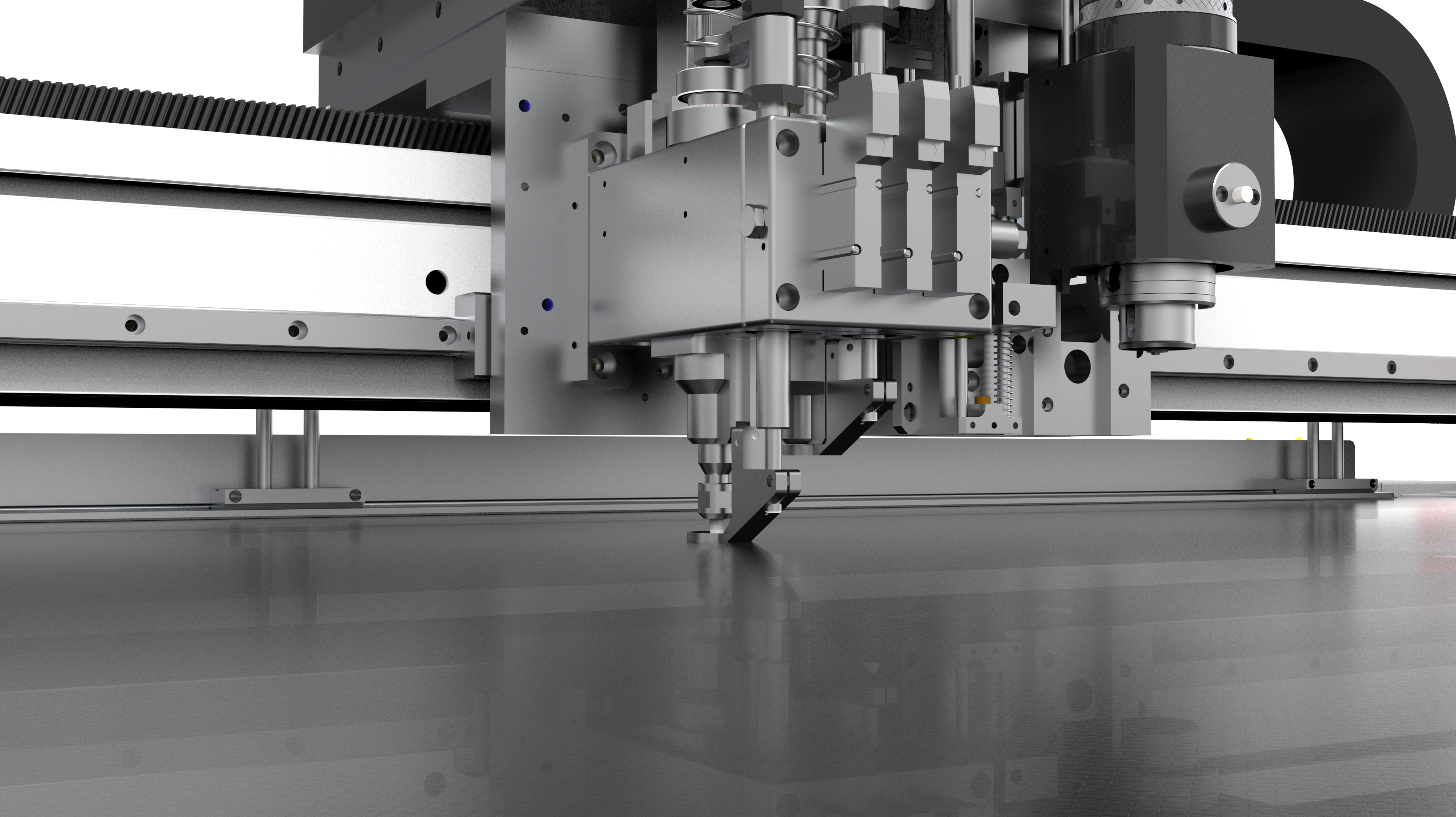

Designed with industrial-scale performance in mind, this equipment provides unmatched control over every detail of the cutting process. Using smart motion systems and powerful control software, the machine ensures each cut is exact, minimizing waste while maximizing productivity.

The Role of CNC in Packaging Innovation

At the heart of the machine lies CNC (Computer Numerical Control) technology. The CNC cardboard cutter is engineered to convert digital box designs into precise, real-world cuts with extraordinary accuracy. This eliminates the need for manual templates or physical dies, reducing preparation time and allowing for immediate design changes.

Factories can now shift quickly between box types, sizes, and formats—ideal for just-in-time manufacturing, seasonal promotions, or handling diverse product lines. The CNC cardboard cutter integrates seamlessly with CAD/CAM software, creating a streamlined workflow from design to production. This digital advantage allows for full customization while maintaining the speed and efficiency of mass production.

Full Automation with Intelligent Control

What sets this solution apart from traditional systems is its integration of automation across every step. As a high-performance automatic box cutter, it features automatic material feeding, precise alignment, smart sensor calibration, and real-time quality control. Operators can manage the entire production process from a user-friendly touchscreen interface, minimizing the need for manual labor and reducing error rates.

Whether producing 10 boxes or 10,000, the automatic box cutter can scale effortlessly to meet production targets. The machine’s automatic tool-changing system further enhances productivity, allowing it to handle different materials and cutting tasks without downtime.

Engineered for Versatility and Precision

Flexibility is one of the defining strengths of the carton box cutting machine. Capable of processing single-wall, double-wall, and triple-wall corrugated cardboard, the system supports a wide range of applications—from shipping cartons to protective packaging and retail-ready boxes. It also supports scoring, creasing, and perforating functions, making it a complete packaging solution in one machine.

Thanks to its high-precision blades and intelligent pressure adjustment system, the carton box cutting machine can consistently deliver clean edges and sharp folds without damaging the material. This is critical for ensuring the structural integrity of packaging during transportation and shelf display.

A Smarter Investment for Smart Factories

As factories move toward Industry 4.0, integrating smart equipment like the carton cutter machine is no longer optional—it’s essential. The machine’s real-time diagnostics, IoT connectivity, and predictive maintenance features make it a true fit for smart manufacturing environments. Operators can track performance data, monitor wear-and-tear, and schedule maintenance to avoid unexpected downtime.

The carton cutter machine also plays a key role in sustainability efforts. Its intelligent nesting software reduces material waste, while energy-efficient components lower power consumption. In addition, the system's ability to create packaging that fits products perfectly reduces the need for filler material and oversized boxes, resulting in less waste throughout the supply chain.

Enhancing Customization and Reducing Time-to-Market

In modern business, customization is king. With the cardboard box cutting machine, manufacturers can offer tailor-made packaging solutions with shorter lead times. Switching from one box design to another is instant and effortless, making it ideal for B2B packaging providers, online retailers, and fulfillment centers that deal with frequently changing SKUs.

The high-speed production capabilities also mean that even customized orders can be completed in bulk without sacrificing quality or delivery schedules. Brands can quickly adapt packaging for promotions, holidays, or regional differences—creating a dynamic and responsive production strategy.In a world where packaging speed, accuracy, and adaptability are more critical than ever, the Precision Cardboard Box Cutting Machine for Modern Factories stands out as a comprehensive solution. By combining the precision of a CNC cardboard cutter, the automation of an automatic box cutter, and the versatility of a carton box cutting machine and carton cutter machine, this advanced equipment offers a powerful advantage to any manufacturer looking to stay ahead.

Whether your business specializes in logistics, electronics, retail, or e-commerce, this machine offers the flexibility, efficiency, and intelligence needed to deliver next-level packaging. As expectations rise and timelines shrink, investing in cutting-edge solutions like the cardboard box cutting machine is no longer a luxury—it’s a strategic necessity.