Industry Trends: The Growing Demand for Precision and Efficiency

The leather industry is evolving rapidly. From fashion and automotive interiors to furniture and luxury goods, every piece of leather must meet strict quality standards. Traditional cutting methods, relying on manual labor or basic mechanical presses, often struggle with inconsistent cuts, material waste, and slow production cycles. As the demand for high-quality leather products increases, manufacturers need smarter, more reliable solutions to remain competitive.

RUIZHOU responds to this challenge with its advanced leather cutting machine solutions, designed to enhance efficiency, precision, and consistency. These innovations include the highly adaptable leather cnc cutting machine and the professional-grade cnc leather cutter, which automate the cutting process and ensure every piece meets exact specifications.

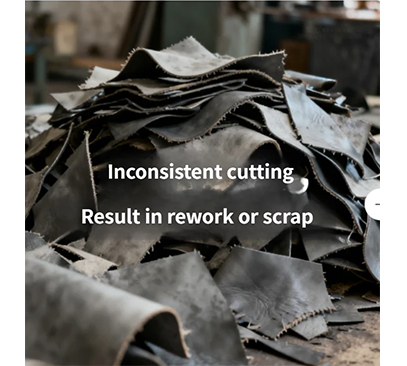

Customer Challenges: Where Traditional Cutting Falls Short

Manufacturers using traditional methods often face:

Inconsistent cuts leading to defects or rework

High material waste due to inaccurate patterns

Slow production cycles, delaying deliveries

Limited flexibility for complex or customized designs

RUIZHOU’s leather cutting machine lineup addresses these pain points. By leveraging CNC technology, these machines reduce human error, optimize material usage, and accelerate production while maintaining high-quality standards.

Our advantage

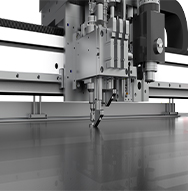

1. Precision and Consistency

The RUIZHOU leather cnc cutting machine ensures every cut is precise, regardless of leather type or thickness. From soft lambskin to durable cowhide, the machine maintains consistent quality across large production runs.

2. Enhanced Efficiency

Automated workflows allow manufacturers to cut multiple pieces simultaneously, reducing production time and labor costs. The smart cnc leather cutter can be programmed with intricate patterns, supporting high-volume orders without sacrificing accuracy.

3. Customization

Understanding that no two manufacturers are the same, RUIZHOU provides tailored leather cutting machine solutions. Clients can customize patterns, software integration, and workflow settings to match specific production requirements.

4. Sustainability

By optimizing cutting layouts and reducing material waste, RUIZHOU machines help leather manufacturers operate more sustainably. Reduced scrap translates to lower costs and a smaller environmental footprint, aligning with modern consumer expectations for eco-friendly products.

1

Comprehensive Service

RUIZHOU does more than supply machines. Every leather cutting machine purchase includes:

Installation guidance

Operator training

Maintenance support

Workflow optimization consultation

This holistic approach ensures clients can transition smoothly from traditional methods to automated systems, maximizing ROI and production efficiency.

2

Industry Impact: Staying Ahead of the Curve

Automation is no longer optional—it’s essential for competitiveness. Brands adopting RUIZHOU’s leather cnc cutting machine and cnc leather cutter benefit from:

Faster turnaround times

Reduced labor dependency

Higher production quality

Flexibility for bespoke designs

These advantages position manufacturers to meet modern industry demands and scale operations effectively.

RUIZHOU’s leather cutting machine, leather cnc cutting machine, and cnc leather cutter solutions represent a transformative leap for leather manufacturing. By combining precision, efficiency, customization, and sustainability with unmatched customer support, RUIZHOU empowers businesses to innovate confidently and maintain a competitive edge in the global leather industry.Upgrade your production today with RUIZHOU and experience the next level of leather cutting technology.