In today’s fast-paced and quality-driven leather goods industry, precision, speed, and efficiency are no longer luxuries—they're non-negotiable. Manual leather cutting, while traditional, is increasingly outdated. It is prone to human error, material wastage, slow processing times, and inconsistent results. To meet the growing demand for smart manufacturing, businesses must now embrace automated solutions. That’s where our advanced CNC leather cutting machine comes in—offering revolutionary speed, pinpoint accuracy, and intelligent performance all in one system.

Digital precision cutting, smarter cutting methods

The key strength of this technology lies in its ability to digitize the entire leather cutting process. By integrating a powerful visual recognition system with proprietary software, this machine transforms digital designs into flawless, real-world cuts. The CNC leather cutter works by reading design files, nesting patterns automatically for optimal material usage, and calculating cutting paths instantly. With this, manufacturers not only save time but also significantly reduce material waste.

Unlike traditional methods, the leather cutting CNC machine operates without the need for dies or molds. The system’s flexibility allows it to switch between various shapes and designs with zero physical tooling, making it ideal for short runs, customized products, or high-frequency design changes. Whether it's small accessories or large automotive upholstery, the same machine adapts to your production needs instantly. This is where real efficiency meets intelligent automation.

Why is this leather CNC cutting machine different?

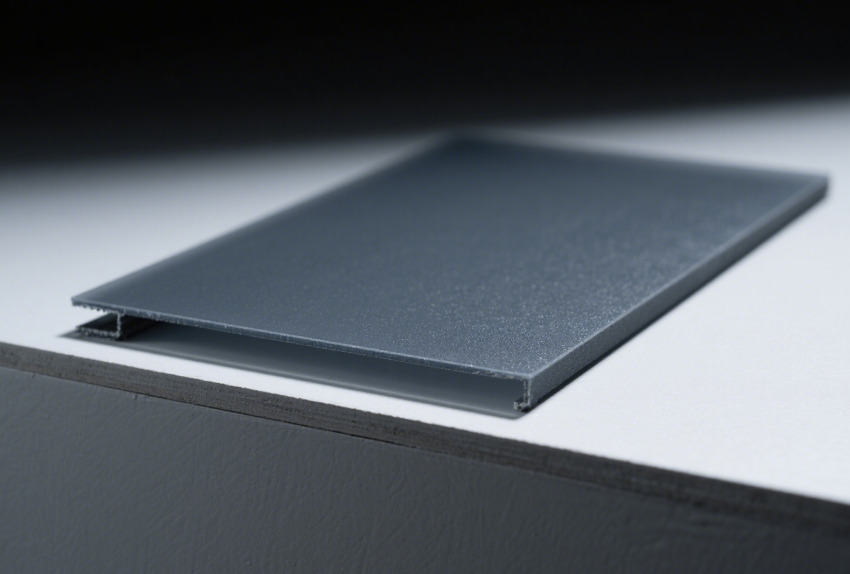

Its cutting system utilizes a high-frequency oscillating blade, capable of cleanly slicing through real leather, microfiber, PU, PVC, and other synthetic materials. With the assistance of vacuum suction tables, the material is fixed firmly during the cutting process, ensuring high-precision results even on curved edges and detailed patterns. The leather cutting CNC platform also includes user-friendly controls and touchscreen interfaces, allowing operators to monitor, adjust, and execute jobs with minimal training. This makes the entire process more streamlined and operator-independent.

Another major benefit is the seamless integration with your digital production workflow. This leather CNC cutting machine supports direct file imports from CAD software, barcode-triggered job activation, and real-time process monitoring. It supports batch processing as well as just-in-time manufacturing models. If you are running a smart factory or upgrading toward Industry 4.0, this system fits right in.

Maintenance is minimal. The machine is designed with industrial-grade durability and equipped with remote diagnostic tools. This ensures low downtime and high operational availability. Most users report a dramatic improvement in overall production efficiency within weeks of deployment. The investment in a CNC leather cutting machine often pays for itself within the first year of operation, thanks to reduced labor costs, better material yields, and faster delivery times.

In applications ranging from footwear, handbags, leather garments to car interiors and furniture, this solution proves to be the most adaptive and forward-thinking approach to modern leather cutting. It replaces outdated manual operations with a digital-first strategy—precisely what today’s competitive markets demand. And because the system is modular, upgrades and expansions are always possible.

What sets this leather cutting CNC machine apart is not just its physical components but the intelligence behind every action. With dynamic pressure adjustment, auto blade calibration, material recognition, and AI-powered nesting software, every step is optimized without human intervention. This results in repeatable quality with negligible errors and unmatched material efficiency.

Why choose our CNC leather cutting machine?

Companies seeking to scale, automate, and modernize should no longer question whether to invest in automation—but which machine to choose. Our leather CNC cutting machine is built for forward-thinking manufacturers who value speed, consistency, and innovation. It's not just an upgrade—it's a transformation.

Choose precision. Choose speed. Choose the future of leather production with our CNC leather cutter—the intelligent machine that’s already shaping the next generation of craftsmanship.

Looking to upgrade your leather processing capabilities? Our CNC leather cutting machines are ready to transform your productivity, precision, and product quality. Whether you're producing leather goods at scale or custom items with intricate designs, our machines offer unmatched efficiency and accuracy. Contact us today to get a free quote, request a live demo, or speak with our specialists about your specific production needs. Let us help you automate smarter, cut faster, and grow stronger. Your next-generation leather cutting CNC solution starts here.