In an era where speed, precision, and customization define competitive success, traditional box production methods are falling behind. Manual labor, outdated tools, and slow setups lead to costly delays and inconsistent quality — all of which negatively impact your business and bottom line.

That’s where the future begins — with a cardboard box cutting machine engineered to handle the demands of today’s fast-paced packaging industry.

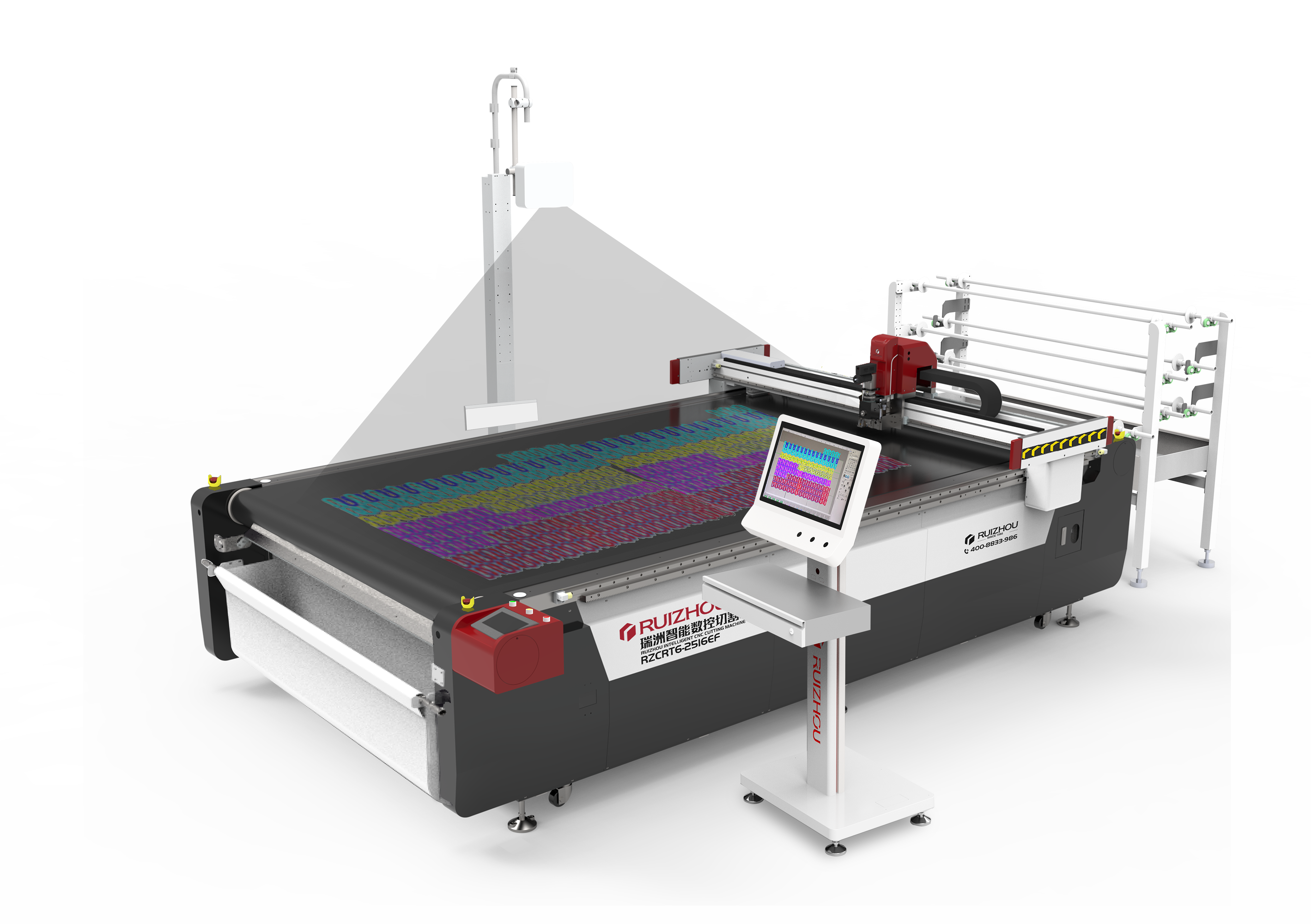

This isn’t just a new machine — it’s a total production upgrade. Powered by intelligent control, advanced blade systems, and precision-driven engineering, the latest cnc cardboard cutter is helping manufacturers and packaging suppliers cut more accurately, reduce lead times, and drastically improve production efficiency. If you’re tired of bottlenecks, errors, or slow box assembly lines, now’s the time to explore the power of automated cutting.

The Problem with Traditional Box Cutting

Manual cutting techniques have been used for decades across packaging facilities. While they served their purpose in simpler times, today’s market is no longer compatible with outdated systems. Growing demands for small-batch runs, customization, complex shapes, and quick delivery schedules have exposed serious flaws in conventional methods:

Inconsistent cut quality

Wasted material due to human error

Long setup times and frequent tool changes

Difficulty meeting urgent or custom orders

High labor and training costs

Even semi-automated machines often lack the intelligence or flexibility required for modern packaging demands.

That’s why the rise of the automatic box cutter is not just a trend — it’s a necessity.

1

What Makes the Cardboard Box Cutting Machine a Game-Changer

At its core, a next-gen cardboard box cutting machine is designed to replace slow, wasteful processes with intelligent, rapid, and repeatable workflows. It combines hardware precision with smart software, allowing for digital input, real-time adjustments, and automated output.Here’s what sets it apart:

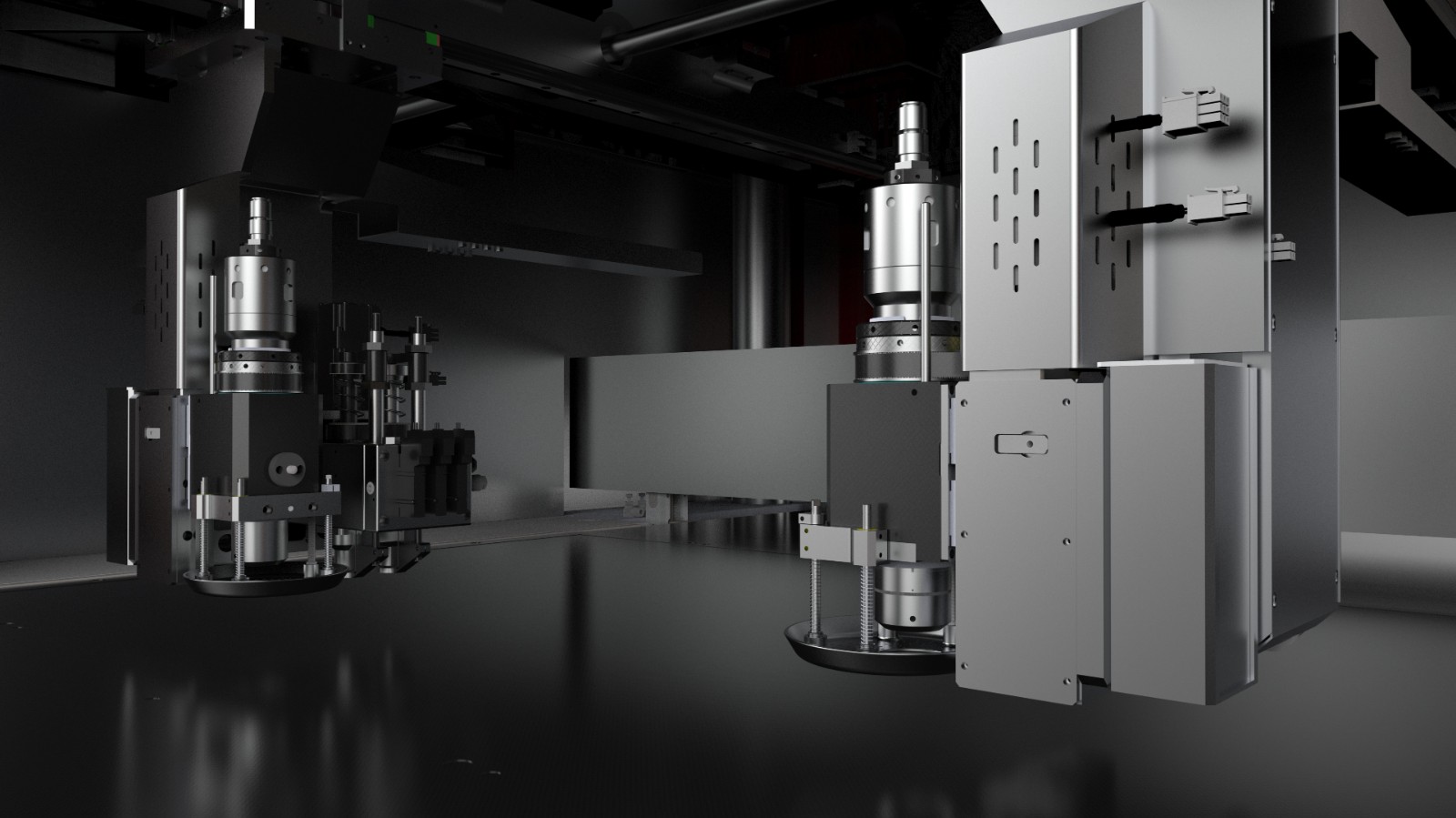

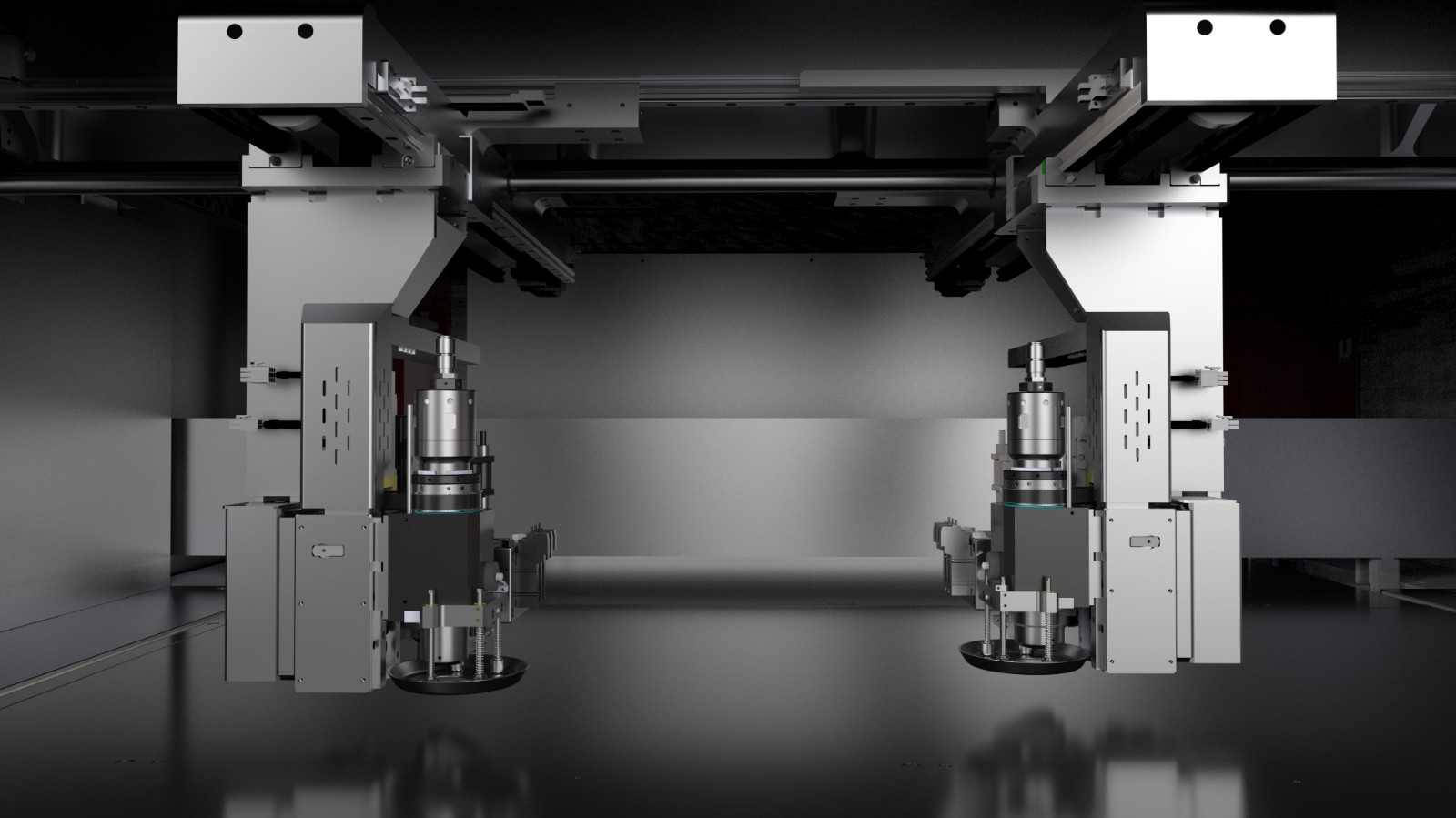

1. Unmatched Precision

Using servo-controlled motion and high-resolution blade positioning, the machine delivers flawless cuts — no jagged edges, no alignment issues, no missed corners.

2. Full Automation

Once set up with a design file, the automatic box cutter runs independently, handling sheet feeding, cutting, creasing, perforating, and even stacking with little to no human intervention.

3. Smart Interface

Touchscreen controls and design-import software allow operators to switch designs instantly. Whether it’s a batch of standard boxes or a one-off custom shape, the system adapts seamlessly.

4. Versatile Applications

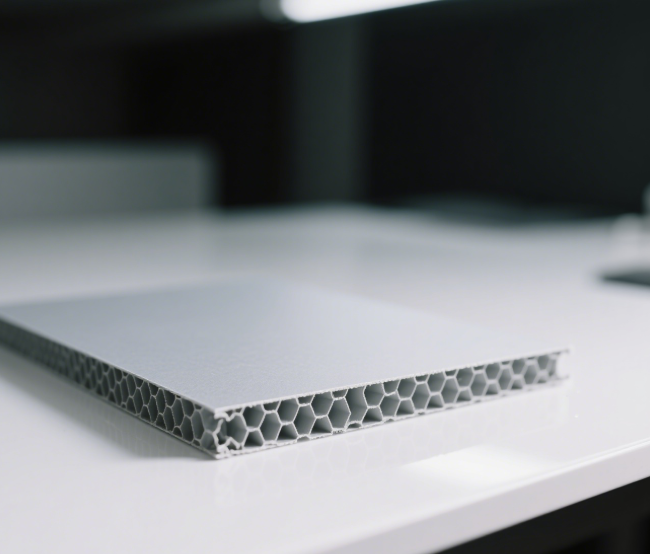

It’s not just for one type of cardboard. Whether you’re working with kraft board, honeycomb board, or multilayer corrugated sheets, the corrugated cardboard cutting machine handles it all with ease.

What to Look for When Choosing a Cutting Machine

When investing in a cardboard box cutting machine, choosing the right equipment is key. Here are five must-have features:

CNC control – Ensures accurate, repeatable motion.

Multi-tool head – Allows cutting, creasing, and scoring in one pass.

Material compatibility – Must handle various grades of corrugated and flat cardboard.

Smart software integration – Enables design import from CAD or packaging software.

After-sales support – From training to troubleshooting, reliable service makes all the difference.

Machines like the corrugated cardboard cutting machine from RUIZHOU and other leaders are built with durability, precision, and customization in mind — and can be tailored to your unique production needs.

From Slow to Scalable: Production Results That Matter

Companies that have switched to a smart carton cutter machine are seeing tangible results almost immediately. Here are just a few of the benefits being reported:

30% to 60% increase in production capacity

Up to 50% reduction in material waste due to optimized cutting paths

95% decrease in manual errors

Dramatic cut in lead times for custom or urgent orders

Return on investment in less than 12 months

One European packaging facility replaced three outdated cutting stations with a single automatic box cutter — and not only doubled output, but also reduced labor needs by 40%. The system's speed and adaptability allowed them to take on new clients and offer same-day packaging solutions.

Whether you're a startup or an established factory, the benefits of upgrading to a cnc cardboard cutter are clear. You’ll eliminate inefficiencies, reduce manual tasks, improve product consistency, and gain the flexibility to meet shifting customer demands.

Plus, with sustainability being a growing concern, optimized cutting paths reduce waste, and many machines now come with energy-efficient components to lower your carbon footprint.

It's Time to Upgrade

The packaging industry isn’t slowing down — and neither should you. The shift to smarter, faster, and more accurate cutting is already underway, and those who adapt early are gaining a powerful advantage.

A cardboard box cutting machine is not just another tool in your workshop — it’s the backbone of a modern, responsive, and competitive production line.

Don’t let slow, outdated methods hold your business back. Explore the new generation of automatic box cutters, embrace the precision of a carton cutter machine, and discover how a true corrugated cardboard cutting machine can change everything.

Your next big packaging innovation might just start with a single cut — made smarter, faster, and better.