In the evolving landscape of textile manufacturing, staying ahead means embracing technology that delivers both speed and precision. The fabric cutting CNC machine stands at the forefront of this transformation, enabling manufacturers to optimize production processes while ensuring superior quality output.

Unlike traditional cutting methods reliant on manual labor, the computerized fabric cutting machine employs computer-guided tools that cut fabric based on exact digital designs. This automation not only improves accuracy but also drastically reduces the risk of human error and material waste.

Future-Proof Your Business with Automation

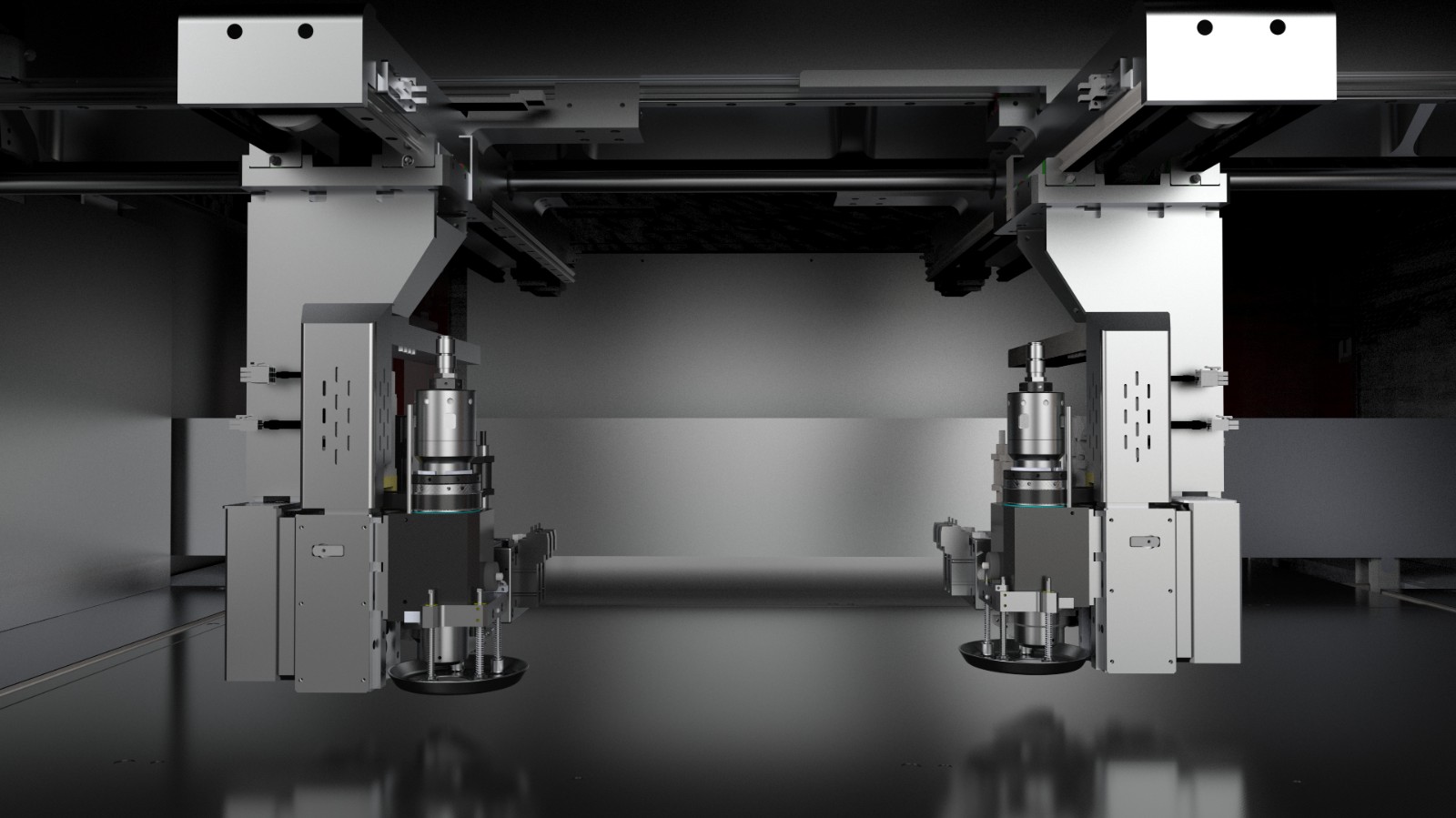

Investing in a computerized fabric cutting machine aligns your operations with Industry 4.0 principles. Automation, data connectivity, and smart manufacturing enable you to meet evolving customer demands while reducing costs and improving quality, securing your competitive edge in the textile market.These machines can operate continuously and handle complex patterns with ease, enabling textile producers to meet demanding deadlines and large order volumes efficiently.

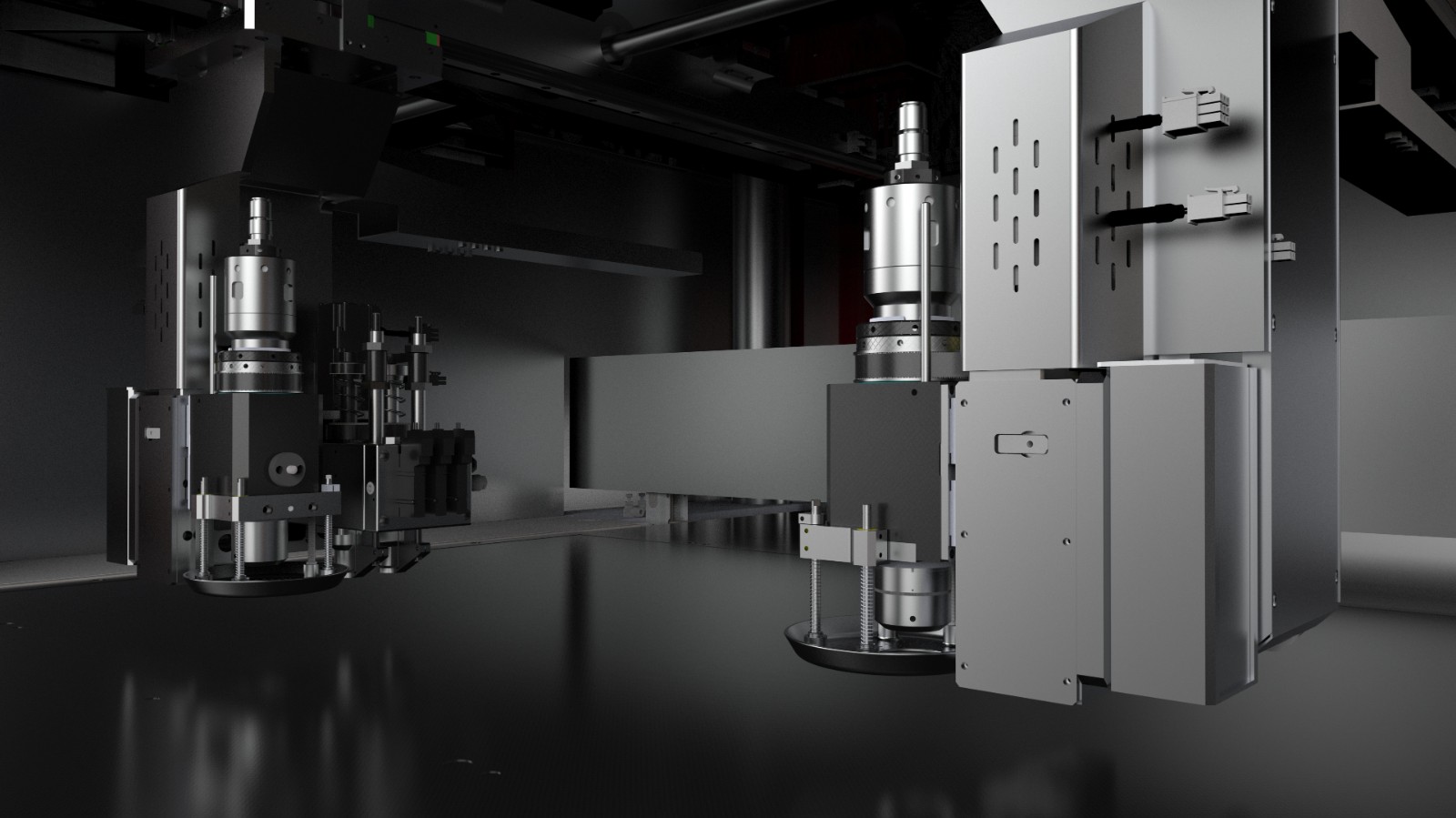

The industrial fabric cutting machine is engineered to handle a diverse range of materials, from delicate silks to heavy-duty industrial textiles. With adjustable settings for blade speed and pressure, the machine ensures every cut is clean and precise, regardless of fabric type or thickness. This adaptability makes it an invaluable asset across various textile sectors.

Precision is paramount in garment production, and the precision fabric cutter excels by delivering perfectly cut pieces that fit together seamlessly during assembly. This accuracy reduces fabric consumption, lowers labor costs by minimizing rework, and enhances the overall product quality. Whether producing bespoke fashion or mass-market apparel, this cutting-edge technology supports every scale of operation.The incorporation of nesting software within the fabric cutting CNC machine ecosystem further optimizes fabric use by automatically arranging patterns to minimize scrap. This software intelligence maximizes material yield and contributes to cost savings, proving vital in an industry where raw material expenses constitute a significant portion of production budgets.

Beyond operational efficiency, the computerized fabric cutting machine offers user-friendly interfaces and straightforward maintenance routines, making it accessible to operators with varying levels of technical expertise. Quick setup times and compatibility with standard design file formats allow seamless integration into existing workflows.

Enhanced Safety and Operator Comfort

Operating an automated fabric cutter reduces manual blade handling and repetitive motions, significantly improving workplace safety. With less direct contact with cutting tools, operators face fewer risks of injuries. Ergonomic designs and user-friendly interfaces also improve operator comfort and productivity.Designed with modular components and self-diagnostic systems, modern industrial fabric cutting machines are easy to maintain. Remote troubleshooting and scheduled maintenance alerts help minimize downtime, ensuring consistent output and protecting your investment.

Choosing the Right Machine for Your Needs

Selecting the ideal fabric cutting CNC machine depends on your production scale, fabric types, and integration needs. Consulting with experts can help you find a tailored solution that maximizes ROI and streamlines your manufacturing process.From fashion and upholstery to automotive and medical textiles, the fabric cutting CNC machine adapts to diverse applications. Its ability to cut various materials with consistent precision makes it an essential tool for industries requiring high-quality fabric processing.

Ready to elevate your textile production with cutting-edge precision and unmatched efficiency? Our fabric cutting CNC machines are engineered to streamline your workflow, reduce material waste, and deliver consistent, high-quality results every time. Whether you’re producing fashion apparel, upholstery, or technical textiles, investing in a computerized fabric cutting machine will give your business the competitive edge it needs to thrive in today’s fast-paced market. Don’t let outdated cutting methods hold you back — upgrade to automation that maximizes productivity and profitability. Discover how our advanced automated fabric cutters can transform your manufacturing process and accelerate your growth. Visit us now at https://www.ruizhoucnc.com/contact to learn more and request a personalized quote. Take the first step toward smarter, faster, and more precise fabric cutting today!