Cutting leather has always been one of the most critical steps in the production of shoes, bags, belts, automotive interiors, and furniture. The method chosen to cut leather directly influences the quality, efficiency, and cost of the final product. Traditionally, craftsmen relied on manual knives, scissors, or rotary tools, but these methods are time-consuming and prone to inconsistencies. In today’s fast-paced and competitive manufacturing environment, businesses require a faster, more precise, and more reliable approach. That is why modern technology points to one clear answer: the CNC leather cutting machine.

Why Precision Matters in Leather Cutting

Leather is a natural material, often expensive, and every piece is unique. Uneven cuts, wasted scraps, or inaccurate shapes not only reduce efficiency but also raise costs. A CNC leather cutting machine solves these problems by using computer-controlled systems that guarantee precision down to fractions of a millimeter. Each cut follows a digital pattern exactly, ensuring clean edges and repeatable results. Whether a factory is cutting delicate sheepskin or heavy cowhide, CNC machines deliver consistent quality, making them the preferred choice for professional manufacturers.

The Role of Modern Leather Cutting Machines

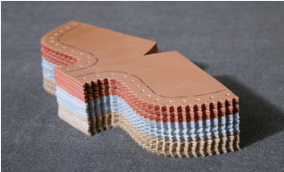

The Role of Modern Leather Cutting MachinesA professional leather cutting machine is more than just a blade. It is a smart system designed to handle different leather types and thicknesses. With advanced software integration, users can adjust cutting speed, depth, and pressure according to the project’s requirements. For example, thin leather for fashion accessories requires a gentle approach, while thick leather for furniture demands more power. By adopting such a machine, manufacturers can expand their product ranges while maintaining top-level precision and efficiency.When production volumes increase, manual cutting or even semi-automatic systems quickly become a bottleneck. An Automatic leather cutting machine eliminates these inefficiencies by streamlining the entire process. These machines automatically align material, optimize nesting to reduce waste, and execute cutting paths without human intervention. The result is faster turnaround, fewer mistakes, and lower labor costs. Factories that integrate automatic leather cutting technology report improved productivity, allowing them to meet growing customer demands without sacrificing quality.

Why a CNC Cutter is the Best All-in-One Solution

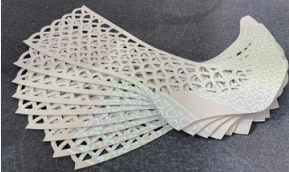

A CNC cutter represents the next evolution in leather cutting technology. Unlike traditional machines, CNC cutters are flexible enough to work with multiple materials in addition to leather, such as textiles, rubber, foam, and composites. This versatility makes them ideal for workshops that produce a variety of products. The digital control system ensures every cut is accurate, repeatable, and efficient. Moreover, CNC cutters reduce material waste by optimizing patterns automatically, helping manufacturers save costs while being environmentally responsible.Not every leather project is straightforward. Fashion brands, luxury goods manufacturers, and automotive companies often require highly customized shapes and designs. This is where a custom leather die cutter becomes invaluable. These machines are specifically designed to cut intricate patterns and unique components that standard cutters may not easily achieve. From decorative stitching panels to logo-shaped patches, a custom die cutter allows brands to create standout products that capture attention in competitive markets.

Traditional methods such as knives or rotary blades require skilled labor, but even the most experienced craftsman cannot match the consistency of a CNC leather cutting machine. Manual cutting often results in uneven edges, material waste, and slower production. On the other hand, modern solutions like Automatic leather cutting machines and custom leather die cutters deliver precision, scalability, and consistency. By upgrading to CNC technology, companies not only improve efficiency but also gain the ability to take on larger and more complex orders with confidence.

Real Benefits for Manufacturers

Investing in modern leather cutting solutions provides several tangible advantages:

1

Higher efficiency

Faster cutting speeds and automation save valuable production time.

2

Lower costs

Less material waste and reduced reliance on manual labor decrease overall expenses.

3

Better quality

Clean, accurate edges improve product appearance and durability.

4

Scalability

From small workshops to large-scale factories, machines can be scaled to match production needs.

As demand for leather goods continues to grow worldwide, the industry will rely more heavily on digital and automated technologies. Companies that embrace advanced solutions such as CNC leather cutting machines and Automatic leather cutting machines will remain competitive by producing consistent, high-quality products faster and at lower costs. The ability to integrate custom leather die cutters also ensures that even the most unique customer demands can be met without compromise.

👉 For more details and to explore our full range of advanced leather cutting machines, visit our official website:www.ruizhoucnc.com

Our team of experts is ready to provide customized solutions to help you achieve efficiency, precision, and growth.