In today’s competitive leather manufacturing industry, efficiency and precision are critical for factory success. This is why many factories are turning to the automated cutting machine as the solution to modern production challenges. Unlike traditional manual methods, an automated cutter ensures faster operations, consistent quality, and reduced material waste, allowing manufacturers to meet increasing customer demands.

Breaking the Limits of Traditional Leather Cutting

Traditional leather cutting methods often rely on skilled labor and manual processes, which can be slow, inconsistent, and prone to errors. Factories face issues like material wastage, high labor costs, and slower production cycles. The introduction of a modern leather cutting machine has revolutionized this process. By integrating automation and computer-controlled precision, factories can now produce leather products at unprecedented speed and accuracy.

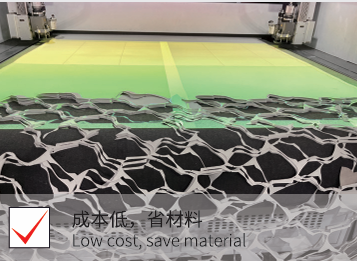

An advanced cnc leather cutting machine combines cutting-edge technology with smart software to optimize every cut. AI-based nesting and automated pattern layouts ensure minimal material waste while maintaining uniform quality across large production batches. This approach transforms leather factories into highly efficient and cost-effective operations.

Key Advantages of Automated Leather Cutting Machines

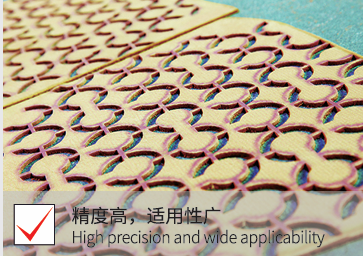

Precision and Consistency – Every cut is controlled digitally, reducing errors and enhancing product quality.

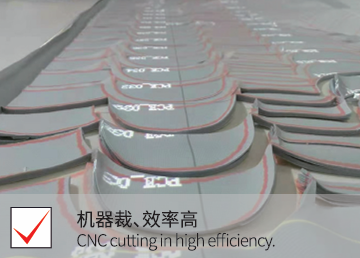

High Efficiency – Multi-layer cutting capabilities allow factories to process more materials in less time.

Labor Savings – An automatic leather cutting machine reduces dependency on manual labor, cutting costs and simplifying workflow.

Material Optimization – Smart software ensures every scrap is minimized, saving valuable leather materials.

Versatility – Supports natural leather, PU, PVC, and other industrial materials.

These features not only boost production speed but also allow factories to take on more complex designs without compromising accuracy. Manufacturers can respond faster to market demands and offer high-quality leather products to clients worldwide.

Real-World Applications

Footwear factories have successfully integrated automated cutting machines to streamline shoe upper production. Automotive interior suppliers use automated cutters for precise seat covers, dashboards, and trims, ensuring flawless cuts that meet international standards. Similarly, luxury handbag and accessory manufacturers rely on leather cutting machines to maintain consistent shape and quality across hundreds of units.

By adopting a cnc leather cutting machine, factories can reduce scrap material by up to 15% and improve throughput by 30% or more. The combination of speed, accuracy, and material savings makes these machines indispensable for modern leather production.

The global shift toward Industry 4.0 has made smart factories the new standard. An automatic leather cutting machine is a core element of this transformation, integrating digital control, AI, and automation to streamline production. This approach reduces human error, maximizes material usage, and allows for flexible, efficient production lines.

Factories investing in automated cutting machines not only secure immediate efficiency gains but also position themselves for long-term growth and competitiveness. They are able to meet the demands of high-volume production while maintaining stringent quality standards.Why choose an automated leather cutting machine for factories? The answer is clear. As industries move toward smarter, faster, and more precise production, automated leather cutting solutions are no longer optional—they are essential. With a cnc leather cutting machine or automatic leather cutting machine, factories can achieve higher productivity, cost savings, and consistent quality, paving the way for a more innovative and competitive future in leather manufacturing.

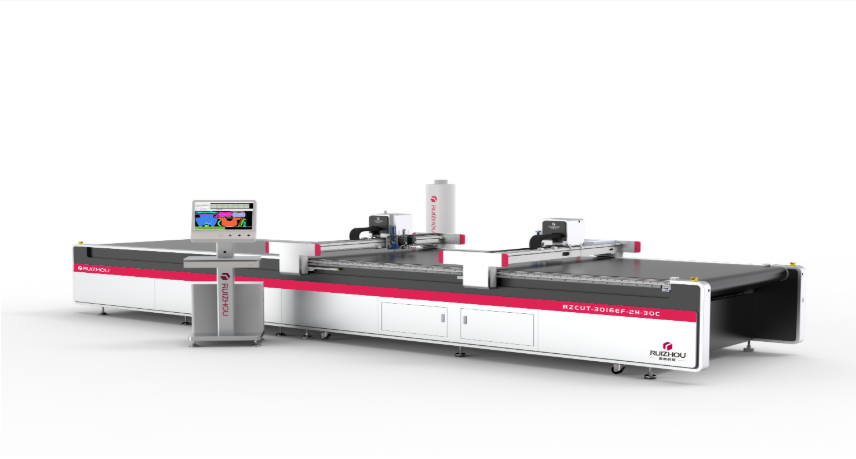

At Guangdong RUIZHOU Technology Co., Ltd., we are proud to provide state-of-the-art automated cutters that meet the demands of modern factories. With intelligent design, advanced automation, and reliable performance, our leather cutting machines help businesses worldwide transform their production processes.

How to contact us

The move toward automation in leather cutting is unstoppable. Investing in an automated cutting machine is an investment in efficiency, quality, and sustainability. Factories that adopt cnc leather cutting machines today will lead the leather industry tomorrow, embracing smarter manufacturing and stronger market competitiveness.

👉 Discover more about our solutions at www.ruizhoucnc.com and see how the latest automatic leather cutting machine can transform your factory production.