Boost productivity with the Precision CNC Leather Cutter for Bags and Upholstery, an automatic leather cutting machine featuring a digital cnc leather cutter system for fast, precise, and clean cuts in industrial leather cutting machine applications.

1.High-Precision Cutting: Our CNC leather cutting machine and CNC cutter deliver smooth, accurate cuts for all types of leather, ensuring professional results with minimal material waste. 2.Smart Automation: Equipped as an Automated Leather Cutting Machine, it streamlines production, reduces labor, and improves efficiency across multiple layers of leather. 3.Versatile & Reliable: This CNC cutting machine is ideal for shoes, bags, upholstery, and custom designs, combining speed, precision, and durability in one intelligent system.

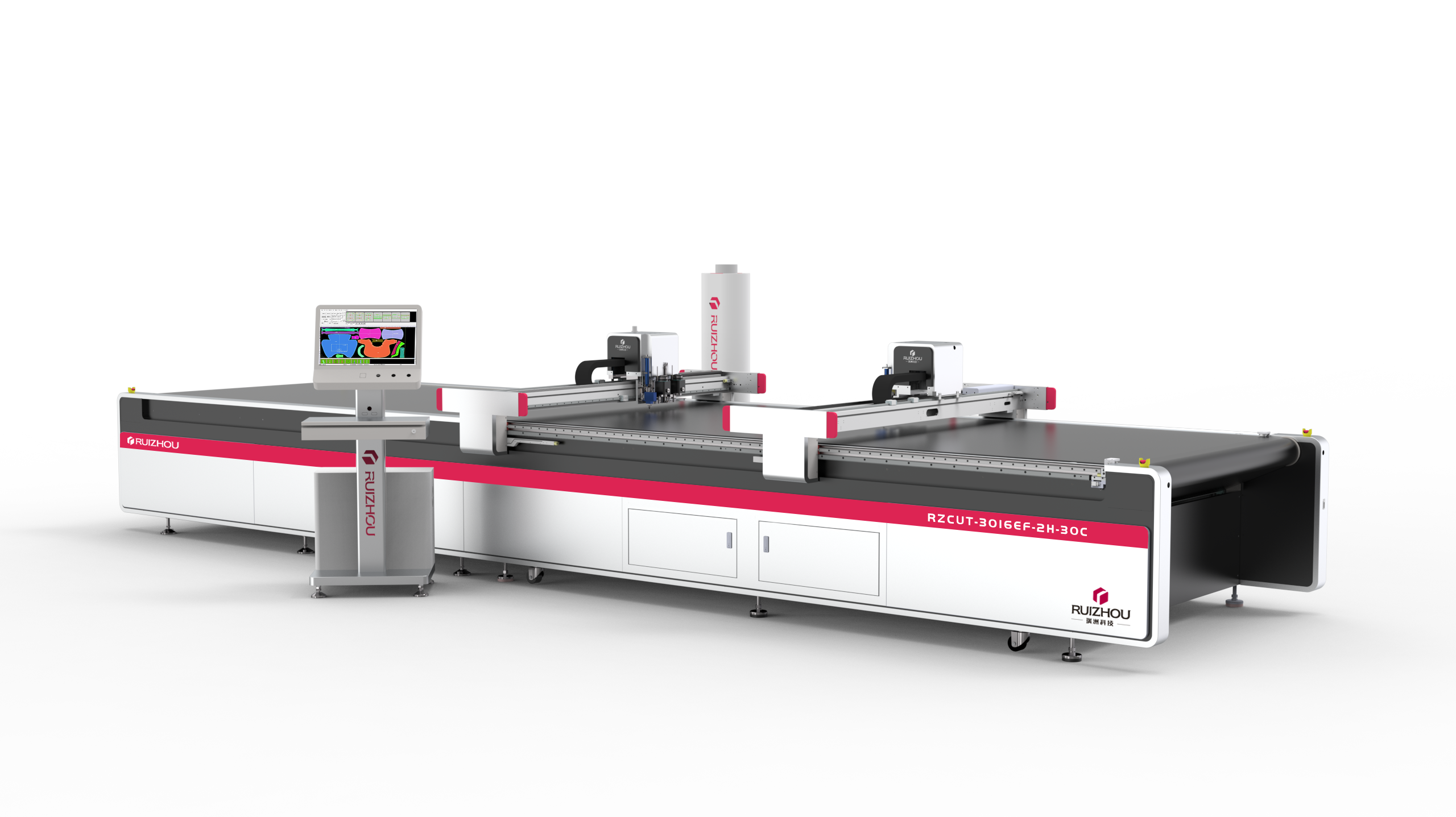

The intelligent process of cutting leather involves three key components: a leather scanning section equipped with the latest Ruizhou Al leather scanning system, a Ruizhou CNC leather nesting and cutting section, and a sorting section. These components work in harmony, facilitating automatic data transmission and establishing a fully integrated system for intelligent digital leather cutting.

By means of Al intelligent nesting algorithm, it can save 3-5% of materials comparing with traditional manual nesting way. And Improve leather utilization and cutting efficiency.

1. China Top Brand High-end CNC Cutting Machines Manufacturer. More Than 28 Years Of Manufacturing Experience. 2. More Than 32,000 Square Meters Of Factory Area. Serving Production Line Projects In 100+ Countries.

Reduce labor costs,improve production response speed reduce the dependence on skilled workers. Speedy detection of different leather defects, automatically capture of leather contour, including cowhide, sheepskin, pigskin, Baby Calf.

1. Al intelligent automatic nesting software and RUIZHOU intelligent server can help to avoid the risk of low efficiency and high fault tolerant rate of manual nesting. 2. Dual cutting beams double cutting efficiency. It meets the production mode of small scale, multiple orders and patterns.

1. China Top Brand High-end CNC Cutting Machines Manufacturer. More Than 28 Years Of Manufacturing Experience. 2. More Than 32,000 Square Meters Of Factory Area. Serving Production Line Projects In 100+ Countries.

Realizing the whole process of leather defect recognition, nesting, cutting and coding intelligent digital management in the shoe industry. And improve leather utilization and cutting efficiency.