Our Ruizhou CNC Leather Shoes Cutting Machine is engineered to deliver exceptional precision and efficiency in leather cutting for footwear production. These advanced machines integrate CNC technology, making them ideal for businesses looking for a reliable CNC leather shoes cutting machine that guarantees accuracy and speed. Whether you need a shoes cutting machine for intricate shoe patterns or a cowhide cutting machine for thicker leather materials, our solutions ensure smooth and flawless operation. Equipped with an oscillating knife cutting machine head, it produces clean, sharp cuts on all types of leather, including soft and tough hides. Perfect for manufacturers in need of a dedicated leather shoes cutting machine, it boosts productivity, reduces material waste, and helps deliver top-quality shoe components with ease.

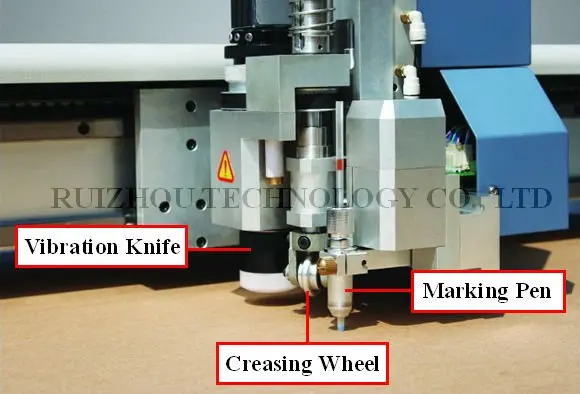

Take a closer look at the advanced cutting head of our Ruizhou CNC Leather Shoes Cutting Machine. This high-precision component is the heart of the digital cutting machine system, delivering seamless and accurate leather cutting. As a powerful CNC leather shoes cutting machine, it effortlessly handles various types of leather, including soft and durable cowhide. The sharp and durable cutting head ensures clean cuts, making it an excellent shoes cutting machine for intricate shoe patterns, while also excelling in tasks that require precision for complex shapes. Equipped with an oscillating knife cutting machine, it delivers both precision and speed, ensuring each piece is cut with exceptional quality. Experience the performance and see how our machine transforms your leather footwear production process!

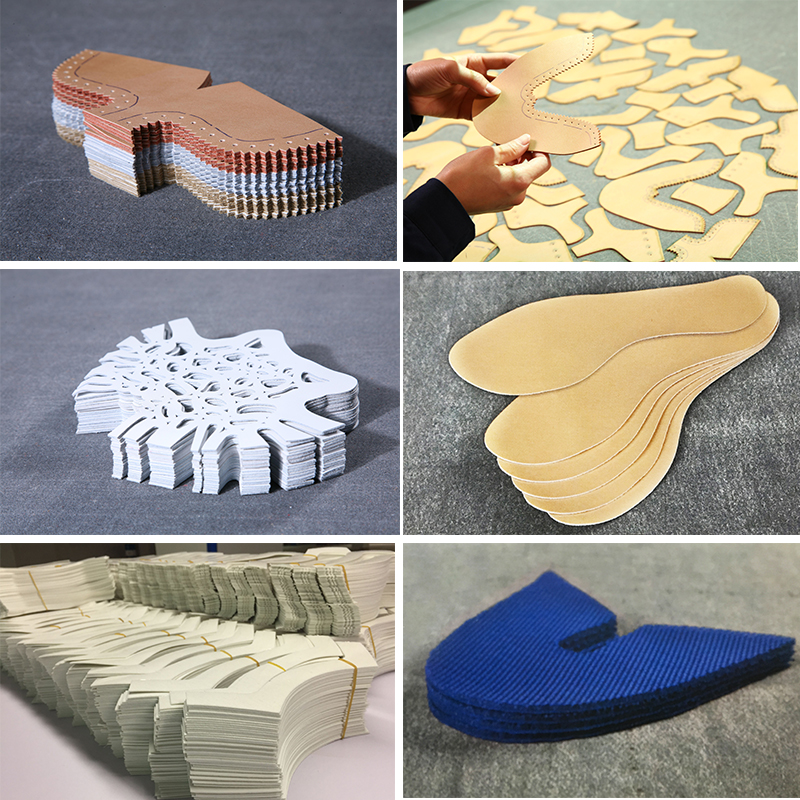

Our Ruizhou CNC Leather Shoes Cutting Machine with an advanced cutting head delivers exceptional performance across a wide range of leather cutting samples. As high-precision leather shoes cutting machines, they provide smooth, accurate cuts and intricate designs, ensuring top-quality footwear components.

For leather applications, the samples highlight the machine’s efficiency as a cowhide cutting machine, producing clean, detailed shapes without fraying. Equipped with CNC technology, it operates as a powerful CNC leather shoes cutting machine, seamlessly handling various leather types and thicknesses. The integration of an oscillating knife cutting machine ensures precise and consistent cuts, even on thick and tough leathers.

Powered by an advanced digital cutting machine system, these samples showcase its versatility and accuracy. Whether you're in the footwear, leather goods, or manufacturing industry, our machine offers a clear advantage, enhancing production efficiency while ensuring superior cutting quality for leather shoes.

| Cutting Speed | 100-1200mm/s |

| Cutting Thickness | 0.1-50mm |

| Nesting | Automatic nesting, improve material utilization |

| Hold Method | Vacuum absorption |

| Machine Language | HP-GL / GP-GL |

| Interface | Ethernet port |

| Accuracy | Less than 0.1mm |

| Available Tools | Pneumatic Oscillating Tool, Pen and Holes Punching Tool |

| Vibration Knife | Electronic, driven by Swiss high frequency motor |

| Cutting Features | 1. Cutting by blade, no laser, no damage on leather. 2. Different types of cutting blades are available to work on various materials and meet different cutting requirements. |

| Air Pump Power | 9KW |

| Machine Working Voltage / Frequency | AC220V±22V / 50Hz±1Hz |

| Air Pump Working Voltage / Frequency | AC380V±38V / 50Hz±1Hz |

Guangdong Ruizhou Technology Co., Ltd., established in 2004 with a registered capital of 11 million yuan, is a key high-tech enterprise under the National Torch Program and a Guangdong Province Intellectual Property Demonstration Enterprise. The company specializes in the research, development, production, and sales of computer-aided design (CAD) systems and computer-aided manufacturing (CAM) equipment. Their products are widely used in industries such as footwear, apparel, leather goods, luggage and handbags, aviation seating, automotive interiors, and packaging. Ruizhou Technology upholds the corporate spirit of "innovation creates value, quality creates efficiency" and holds numerous invention patents and software copyrights. Their products are exported to over 50 countries and regions across Asia, Europe, and the Americas. The company is committed to providing information-based and automated production solutions for traditional manufacturing industries, promoting the transformation and upgrading from "Made in China" to "Intelligent Manufacturing in China."